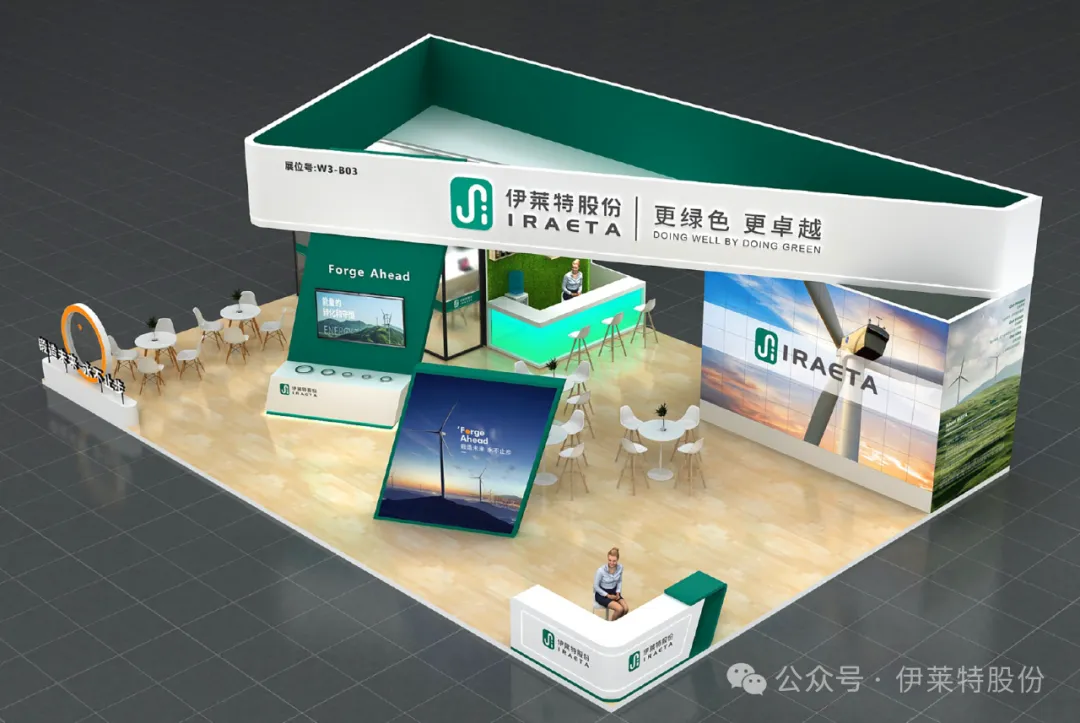

Three Highlights! Iraeta's Booth W3-B03 Packed at the Beijing Wind Energy Expo!

On October 16, 2024, Iraeta showcased three major highlights at the Beijing Wind Energy Expo. Booth W3-B03 was continuously bustling, with industry leaders and guests filling the space.

That morning, as a China–Spain joint venture, Iraeta welcomed Spanish Ambassador to China Marta Betancourt Roig and her delegation to its booth. They were briefed on Iraeta’s recent growth and the progress of its “Integrated Extra-Large Critical Forged Components” project. The Ambassador praised Iraeta’s achievements and encouraged the company to keep advancing Sino-European clean-energy collaboration.

Ambassador Marta Betancourt Roig (fourth from right) tours the Iraeta booth

The Guangdong Electric Power Design Institute of China Energy Construction presented Iraeta with a commemorative banner. Procurement Manager Mengfei Jiang commented, “Forging excellence with low-carbon fire, our giant rings lead the world,” capturing Iraeta’s outstanding accomplishments in wind power. He commended the company’s responsibility and dedication on the Fangchenggang project, noting that the banner symbolizes the partnership’s shared success and bright future.

Guangdong Electric Power Design Institute presents its banner to Iraeta

As a leading player in the global wind-power market, Iraeta made an impressive appearance at this year’s Expo. Through three highlights, the company presented a comprehensive vision of “green forging” to all attendees.

Highlight 1: Dream Big — Unleash Your Imagination

In recent years, backed by supportive policies and technological advances, China’s wind power sector has seen explosive growth. Offshore wind, in particular, has gradually become a cornerstone of the country’s energy transition and a key driver of its marine economy.

However, behind this rapid expansion lies relentless cost-reduction pressure. Strong wind resources, limited sea-area availability, and the demand for low-cost electricity are driving developers to focus on larger-capacity turbines to achieve greater cost efficiency.

As a benchmark champion in wind-flange manufacturing, Iraeta has consistently supplied reliable components for the latest generation of turbines. To date, it has produced flanges for nearly every 10–20 MW model worldwide, including Vestas 15 MW, Goldwind 16 MW, China Huaneng 18 MW, Dongfang Electric 18 MW, and CRRC 20 MW.

Dongfang Electric 18 MW

CRRC 20 MW

Current trends show that next-generation 20 MW+ “super-turbines” are already emerging. Tower diameters are increasing while also demanding lightweight designs, placing higher requirements on material strength and forging equipment capacity.

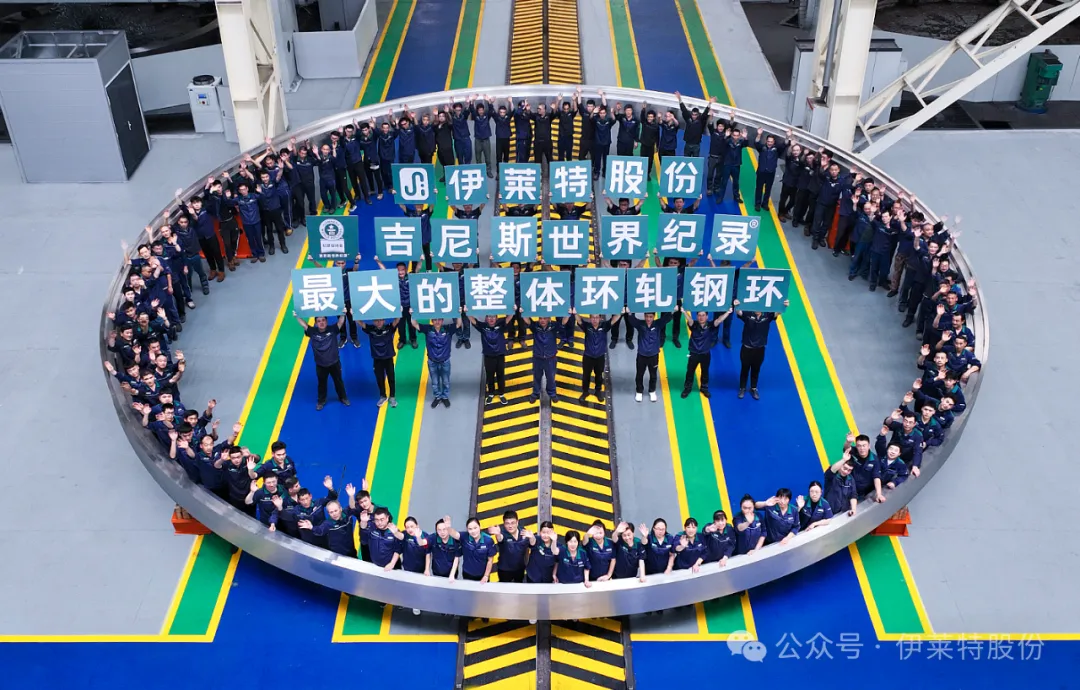

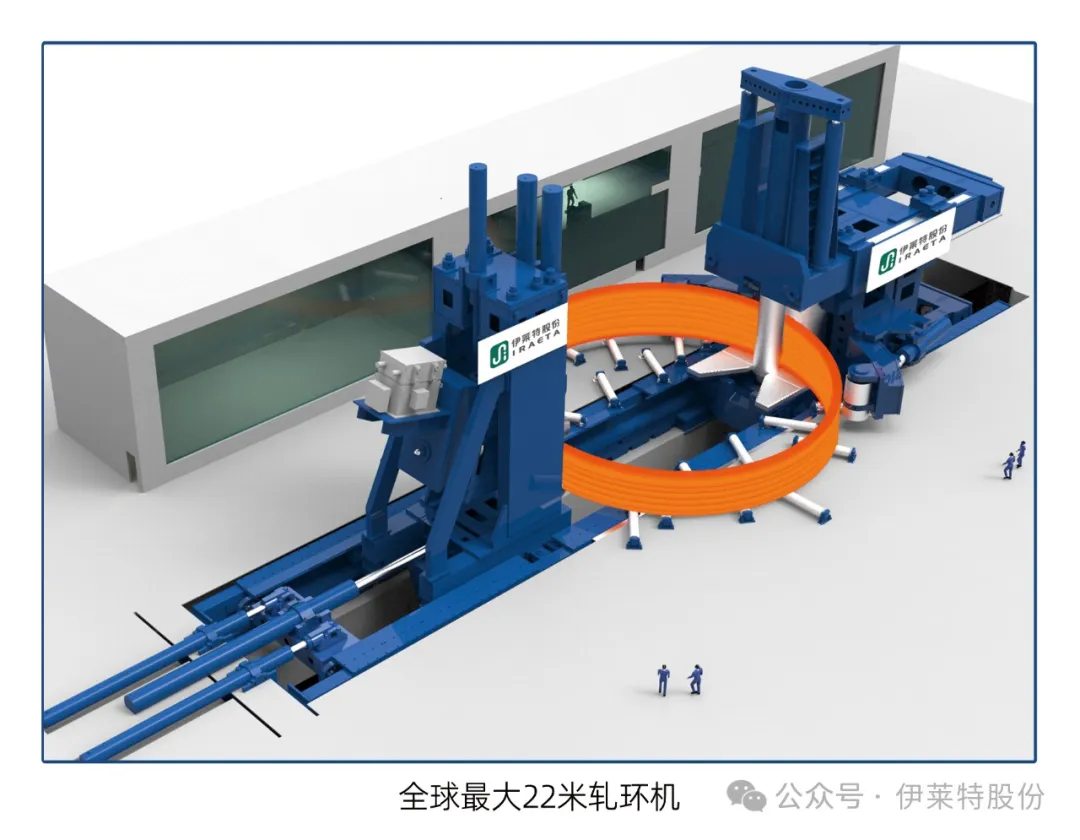

Iraeta is renowned for its Guinness World Record 16 m ring forgings. This year, the company launched the “Integrated Extra-Large Critical Forged Components” project. By installing a 22 m ring mill, a 22,000 t free-forging hydraulic press (the world’s largest), a 21 m heavy-duty vertical lathe, and other advanced equipment, Iraeta continues to push manufacturing limits, opening up new creative possibilities for multi-megawatt turbine design.

The world’s largest 22 m ring-rolling mill

Let’s Forge Ahead Together — Shared Global Resources

Global demand for wind power continues to grow, and China’s wind industry is in its golden “going overseas” period. This calls for coordinated collaboration across the supply chain to advance sustainable offshore wind development.

As a national champion and model in wind-flange manufacturing, Iraeta has spent over 20 years serving the wind-power sector. The company has been deeply involved in offshore wind farms worldwide and operates nine production facilities—with more than 2,200 employees—across China and Spain.

By leveraging group resources, Iraeta offers localized delivery in countries such as Europe, the United States, Brazil, Argentina, India, Turkey, and South Africa. In addition to flanges, towers, gearbox forgings, and slewing-bearing components, the company supplies split rings and mooring chains for offshore turbines.

Iraeta’s Spain Manufacturing Facility

For Chinese OEMs and EPC contractors expanding overseas, partnering with Iraeta ensures dependable local delivery capabilities and shared global resources.

Highlight 3: Truly Recycled, Truly Low-Carbon, Truly On Time, Truly Robust

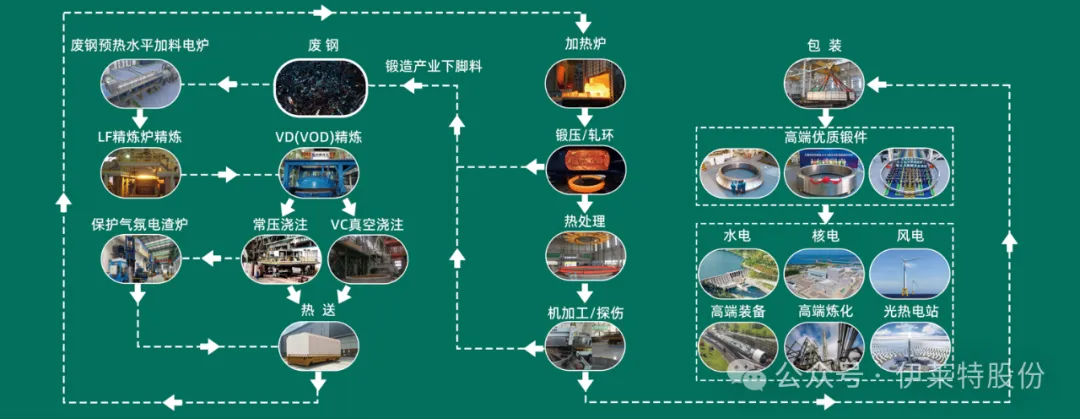

Iraeta operates its own short-loop smelting plant, which recycles forging scrap and off-cuts along with urban and industrial steel waste. The reprocessed steel is brought to 500 ℃ and sent directly to the forging workshop—saving the energy that would be required to heat from room temperature.

Most wind-flange steel in the industry comes from long-loop steelmaking, emitting around 200 t of CO₂ per 100 t of material. By contrast, Iraeta’s short-loop process emits only about 40 t CO₂ per 100 t—a reduction of up to 80%. This dramatically lowers the carbon footprint of the wind-power value chain, helping customers reach peak emissions and carbon neutrality, and enabling zero-carbon turbine and farm construction.

Meanwhile, the in-house smelting plant uses multimodal river–sea transport via the Xiaoqing River to quickly deliver large-diameter flanges to clients—ensuring timely delivery for major offshore projects.

Greener and more outstanding, Iraeta stands ready to join the global wind-power industry in making an even greater contribution to humanity’s energy transition.

Recommended reading

25MW! 12-Meter Diameter! Iraeta Achieves Another New Breakthrough in Offshore Wind Power Forgings

Iraeta Supports France's First Floating Wind Power Forging Project

Deepen Cooperation and Forge Ahead Hand in Hand —— The Chairman of ACEK Group Pays a Visit to the Leaders of Jinan City and Visits Iraeta.

The Startup Ceremony of the First 12.83-meter Semi-autogenous Grinding Ball Testing Machine in China was Held at Iraeta.

12m Wind Tower Flange for 20MW Turbines Rolls Off Production Line at Iraeta.