Seamless Transition Sections

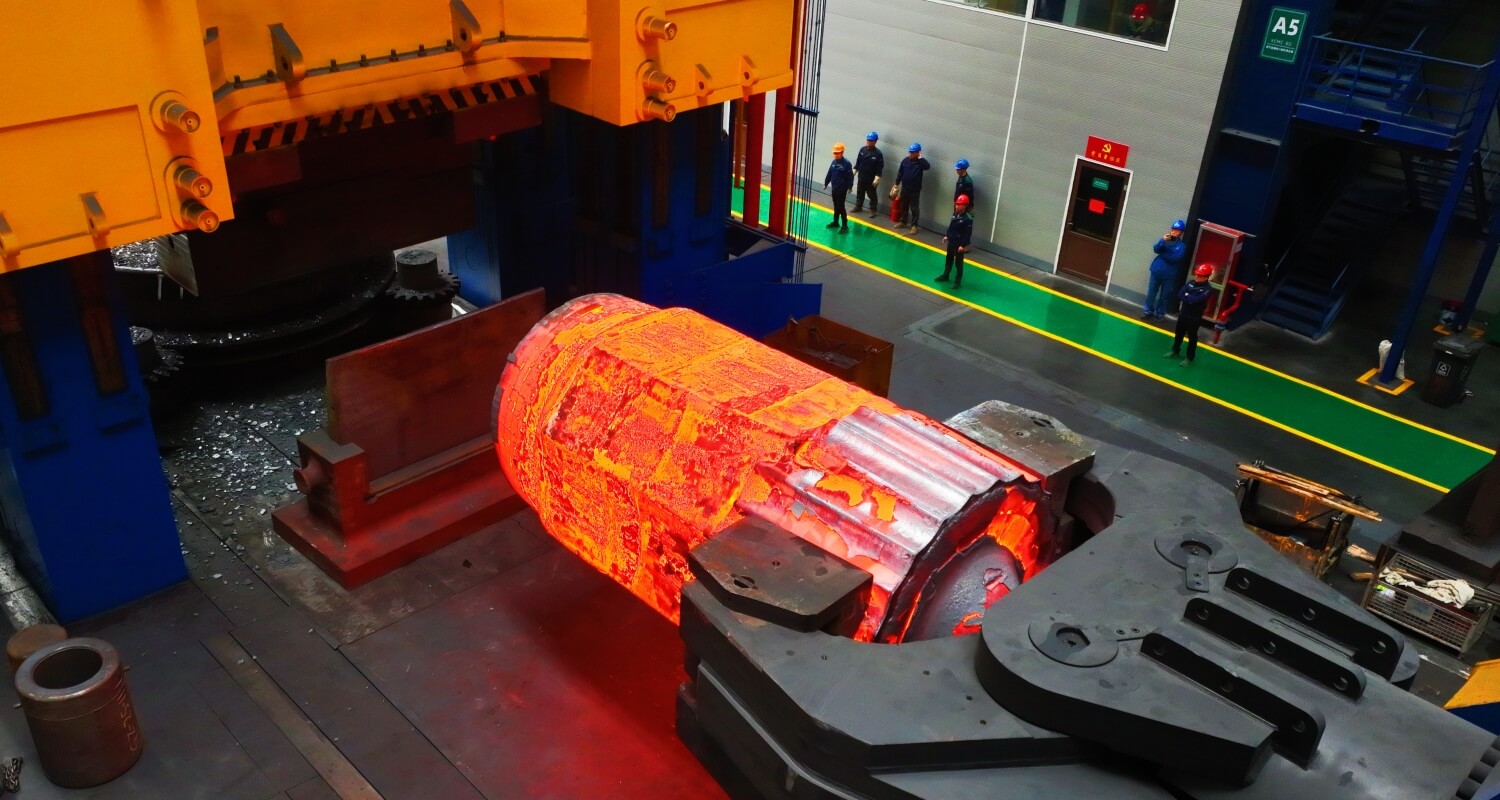

We produce transition sections using the advanced “forging-and-rolling” process (free forging + radial-axial rolling), and we are among the very few manufacturers worldwide with this capability.

For large-diameter pressure vessels, coke drums, and similar equipment, traditional transition sections are usually made by multi-segment welding. At Iraeta, our integrally formed forging-and-rolling process creates a seamless transition section that performs far better under temperature cycling, vibration, and high-pressure conditions compared with welded structures.

Easily Achieve Larger Diameters

While seamless, one-piece transitions can also be made by large forging presses, their diameter is usually limited to about 7 meters due to the press columns.

Using the “forging-and-rolling” process (open-die forging + radial-axial rolling), Iraeta can easily produce transition sections up to the 10-meter range.

Moreover, radial-axial rolling is a continuous forming process. Under high rolling force, the metal flow aligns with the circumference, which significantly improves performance and reduces fatigue cracking.

In-House Steel Mill, One-Stop Solution

We operate our own short-process steel plant and use LF / VD / VOD systems to refine material composition. For critical applications, we can also produce high-purity steel through ESR (Electroslag Remelting). Compared with suppliers without melting capability, our advantages include:

1.Easier material customization: We work with you to fine-tune alloy composition and steel cleanliness for your specific needs. You no longer need to source a separate steel mill or coordinate raw-material schedules.

2.More accurate quality traceability: With a full data chain from melting to forging, heat treatment, and machining, any issue can be traced precisely to the specific heat. This is especially important for first-of-its-kind products and long-cycle, multi-batch projects.

Performance Showcases

Project: Saudi Aramco Jafurah

Type: Y - type Transition Piece

Quantity: 2 pieces

Diameter: 8.6 meters

Project: a large oil refinery in Europe

Diameter: 4.5 meters

Height: 2.5 meters

Project: a large - scale refining - chemical project in China

Type: Transition Piece of Isomerization Reactor

Diameter: 10.1 meters

Business Inquiry

China projects:0531-83800687

Overseas projects:0531-83802699

Or email us at ebiz@iraeta.com

Where Big Ideas Get Forged

We operate a world-class forging cluster, featuring exclusive mills that set us apart in the industry. These industrial powerhouses break through traditional manufacturing limits, empowering engineers to unleash their creativity and bring groundbreaking designs to life.

See Our Power

Green Steel

Most of our raw materials are sourced from our own short-process steel mills, where leftovers from production are recycled. This green cycle plays a crucial role in significantly reducing carbon emissions in our products.

What's Green Steel