Defects in Cast Klin Tyres

The klin tyres are critical components of a rotary kiln. They support the full weight of the kiln, enhance the radial stiffness of the shell, and ensure smooth rotation on the rollers.

Klin tyres made by casting inevitably suffer from various defects: porosity, shrinkage, slag inclusions, cracks, cold shuts, sand holes, impurities, coarse grains, and segregation. These flaws lead to uneven hardness, localized stress concentration, and cracks, causing frequent equipment downtime for repairs. This can result in significant losses for industries such as cement and paper, where operations are continuous, automated, and enclosed.

Our Solution: Replacing Casting with Forging

Forged klin tyres can significantly reduce the inherent defects of cast klin tyres because:

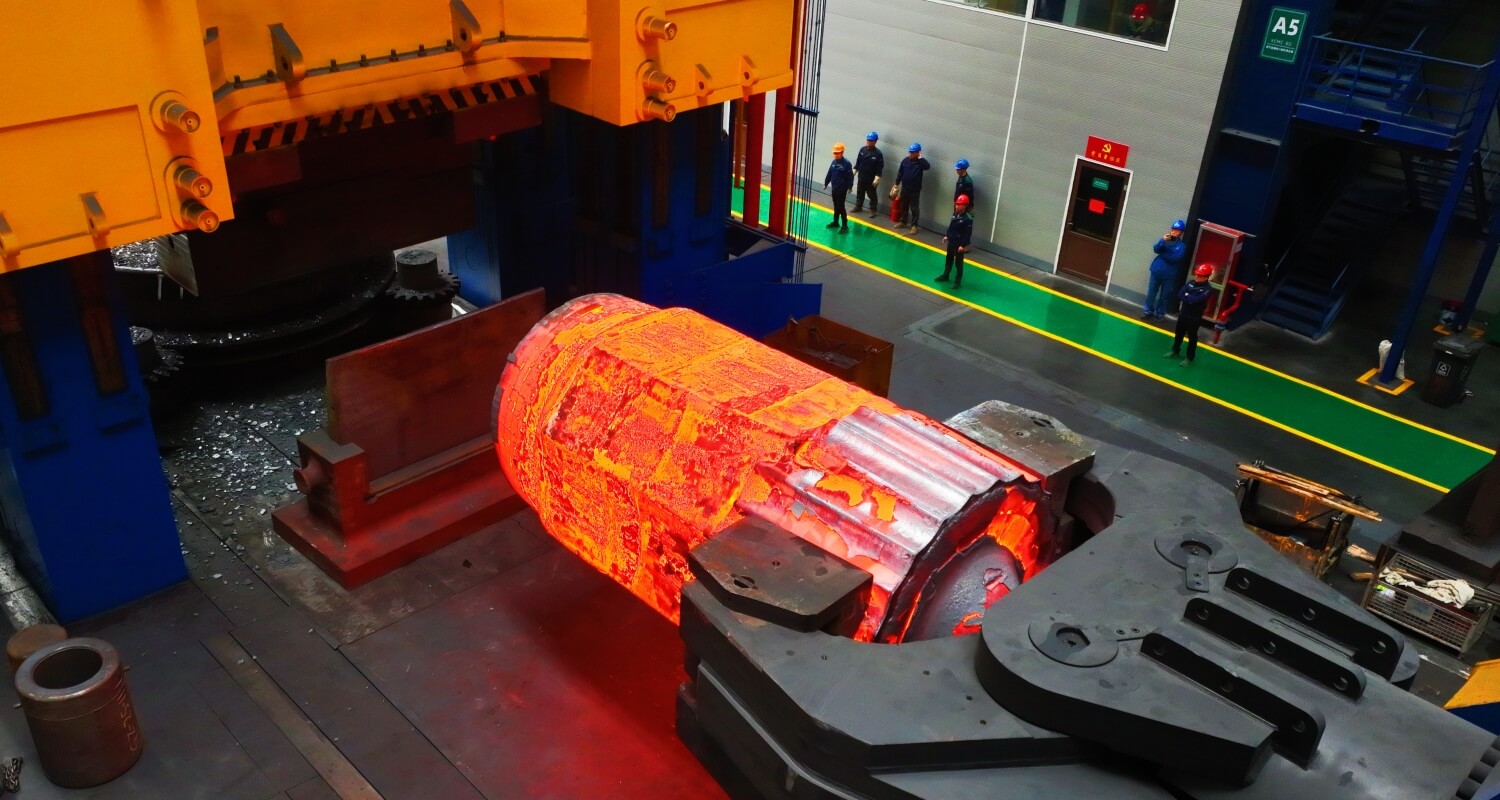

Step 1: Large-deformation multi-directional forging breaks up coarse cast grains and reduces or eliminates internal porosity and looseness, greatly improving the density of the klin tyres.

Step 2: The ring-rolling machine applies strong pressure in both radial and axial directions, aligning the metal structure along the circumferential direction and further enhancing density and mechanical properties.

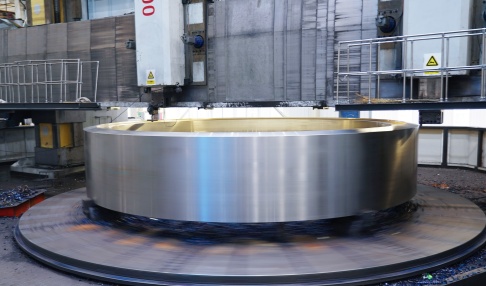

Step 3: Heat treatment is applied to further improve performance, followed by strict non-destructive testing and mechanical inspections after machining.

Highly Favored

Since their introduction, our forged klin tyres have quickly gained favor among leading rotary kiln manufacturers both domestically and abroad. The largest tyres have reached a diameter of 8.6 meters and a weight of 156 tons, and have been used in cement rotary kilns with a daily output of 10,000 tons.

Performance Showcases

Customer: A certain customer in Germany

Diameter: 8.6 meters

Weight: 132 tons

Customer: A certain customer in Denmark

Diameter: 8.3 meters

Weight: 143 tons

Customer: China National Building Material Group Co.,Ltd.

Diameter: 6.1 meters

Weight: 51 tons

Business Inquiry

China projects:0531-83800687

Overseas projects:0531-83802699

Or email us at ebiz@iraeta.com

Where Big Ideas Get Forged

We operate a world-class forging cluster, featuring exclusive mills that set us apart in the industry. These industrial powerhouses break through traditional manufacturing limits, empowering engineers to unleash their creativity and bring groundbreaking designs to life.

See Our Power

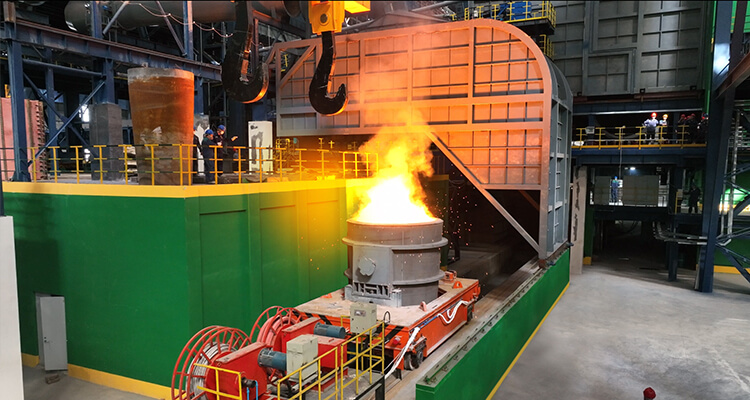

Green Steel

Most of our raw materials are sourced from our own short-process steel mills, where leftovers from production are recycled. This green cycle plays a crucial role in significantly reducing carbon emissions in our products.

What's Green Steel