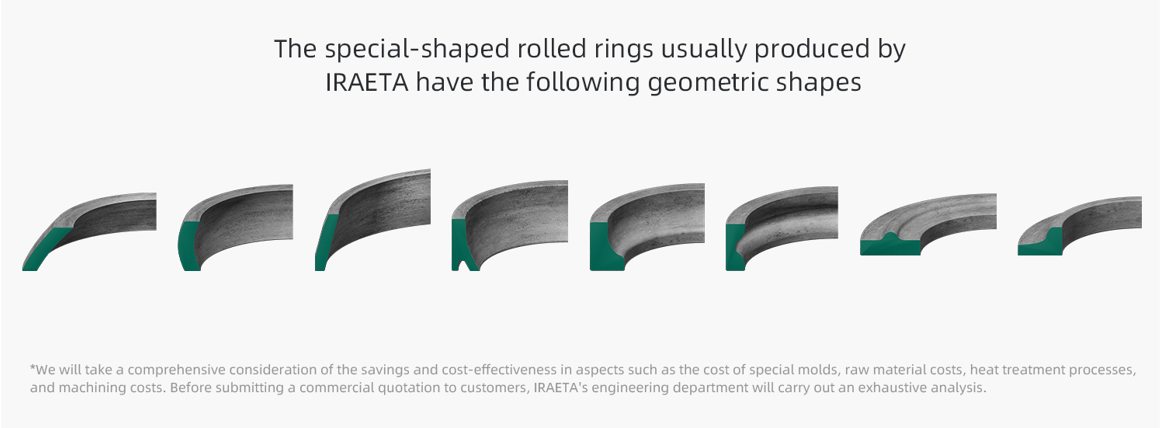

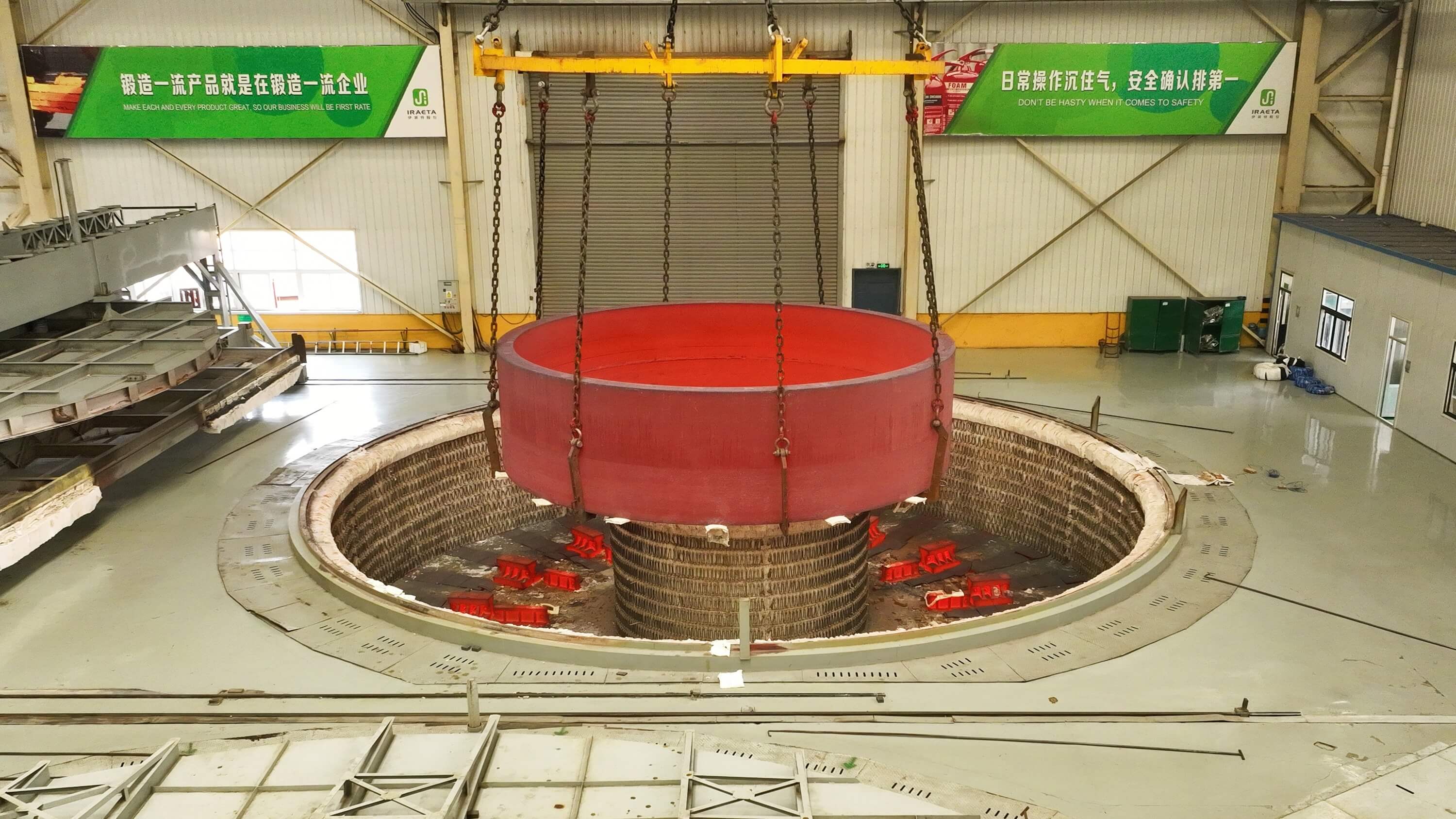

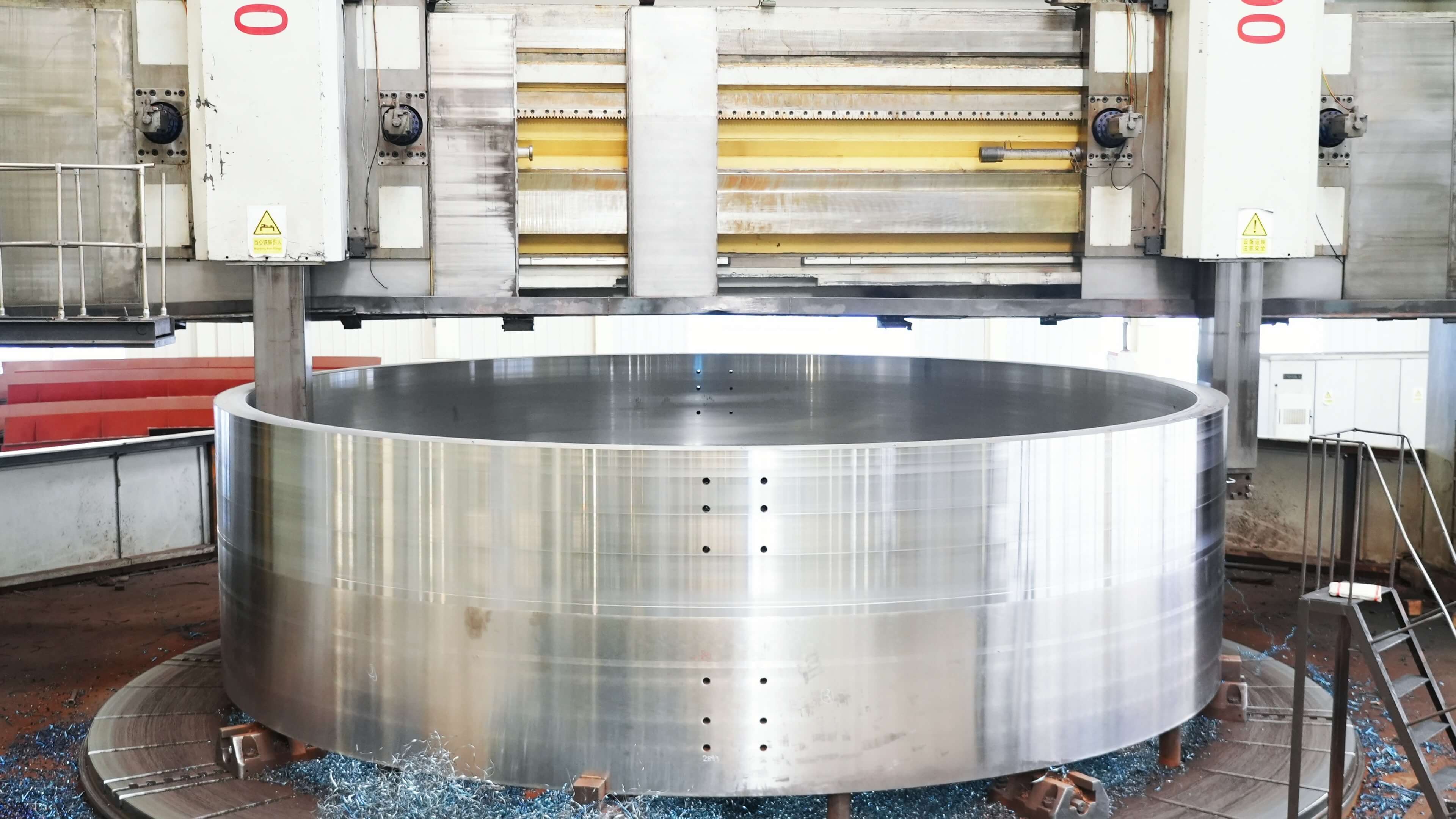

Forging —Customized Rectangular and Profile Ring Rolling

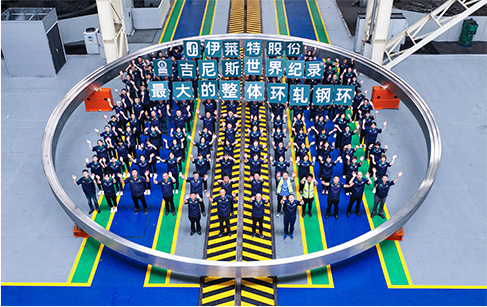

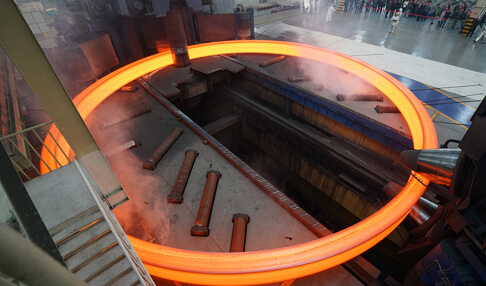

We are equipped with a 22,000-ton free forging press and a 22-meter diameter super ring rolling machine. This robust equipment enables us to confidently tackle various challenges, including the production of rectangular-section and specially shaped rolled rings. Currently, we offer comprehensive customization of ring forgings, covering a full range of specifications: product weights from 0.3 kg to 350 tons, diameters from 73 mm to 22 meters, and heights from 12.5 mm to 5 meters.

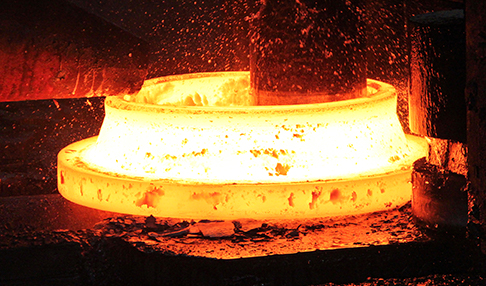

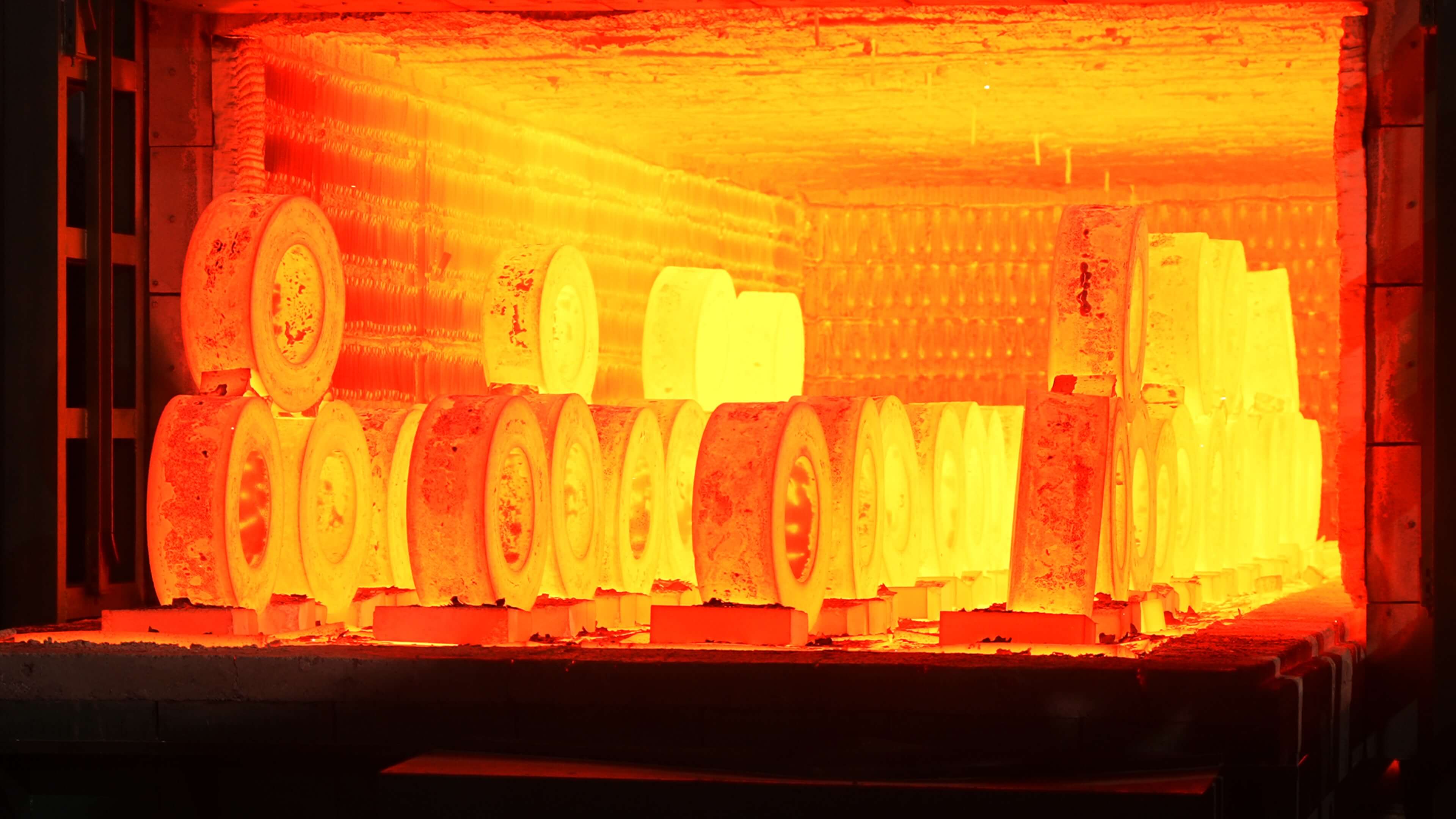

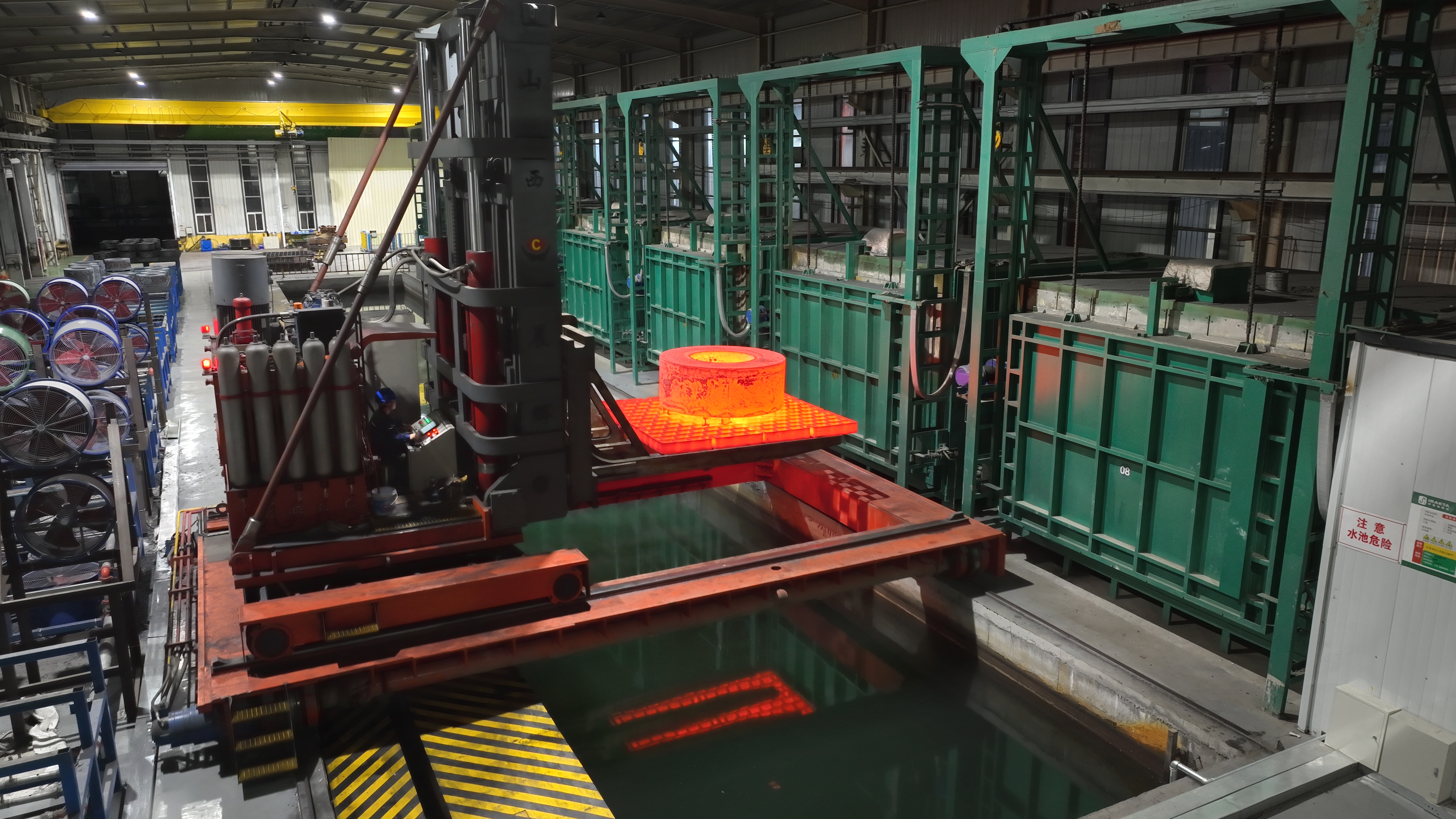

Heat treatment —Delivering High Standards for All Thermal Processing Needs

Heat treatment processes play a pivotal role in enhancing the mechanical properties of metals, including strength, hardness, toughness, and wear resistance. At Iraeta, our dedicated heat treatment team employs a scientific and meticulous approach to thermal processing, ensuring that each metal component meets the highest quality standards. By optimizing heat treatment methodologies, we produce superior metal products that fulfill the stringent requirements of various industries.

The heat treatments performed at Iraeta are as follows:

N (Normalized)

T (Tempered)

QT (Quench and Tempering)

AT (Solution Annealing)

A (Annealed)

+ FP or + N + T (Normalizing and Tempering)

Solution and precipitation hardening (solution treatment + aging treatment)

Stress relief

Other combinations

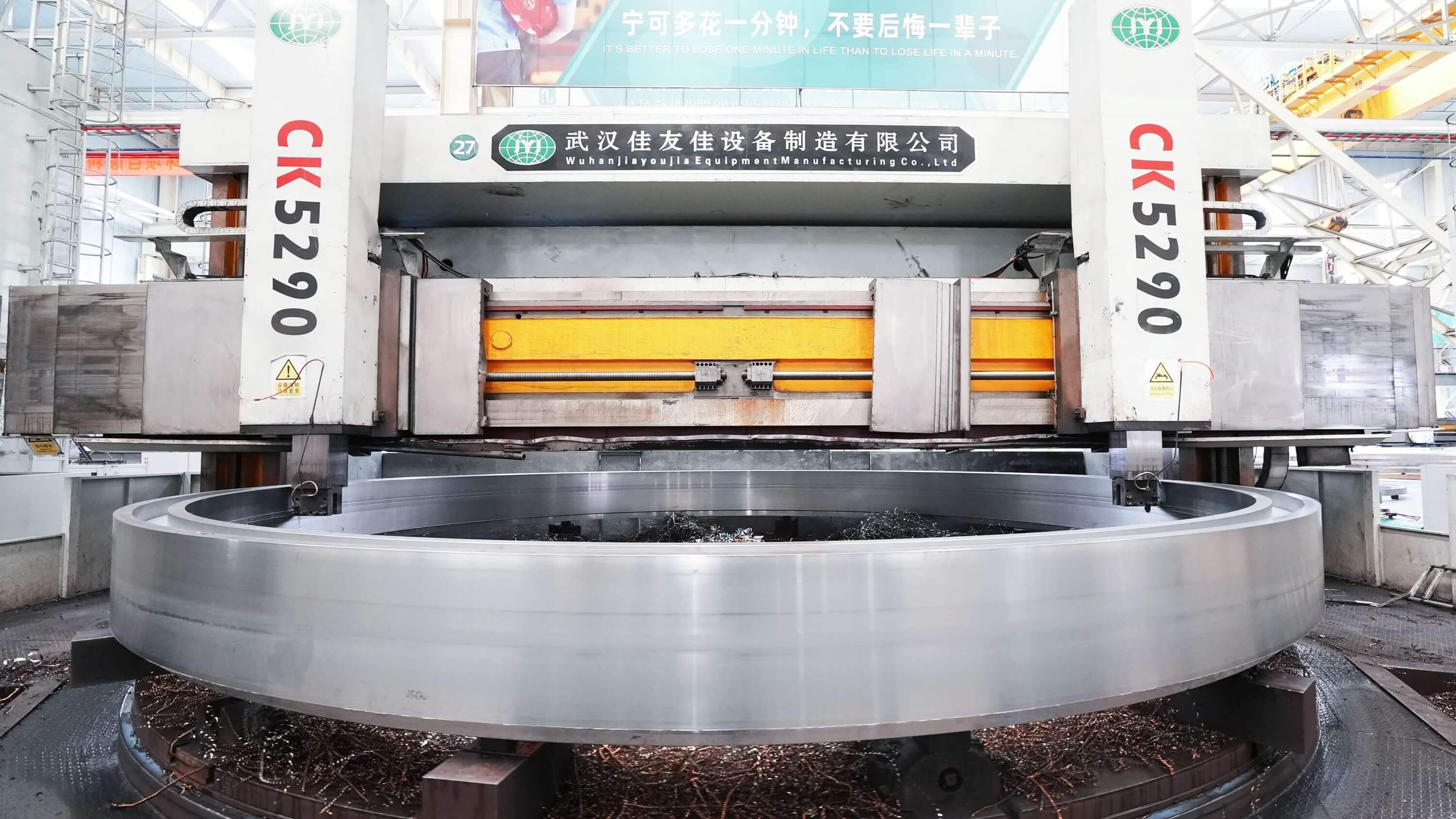

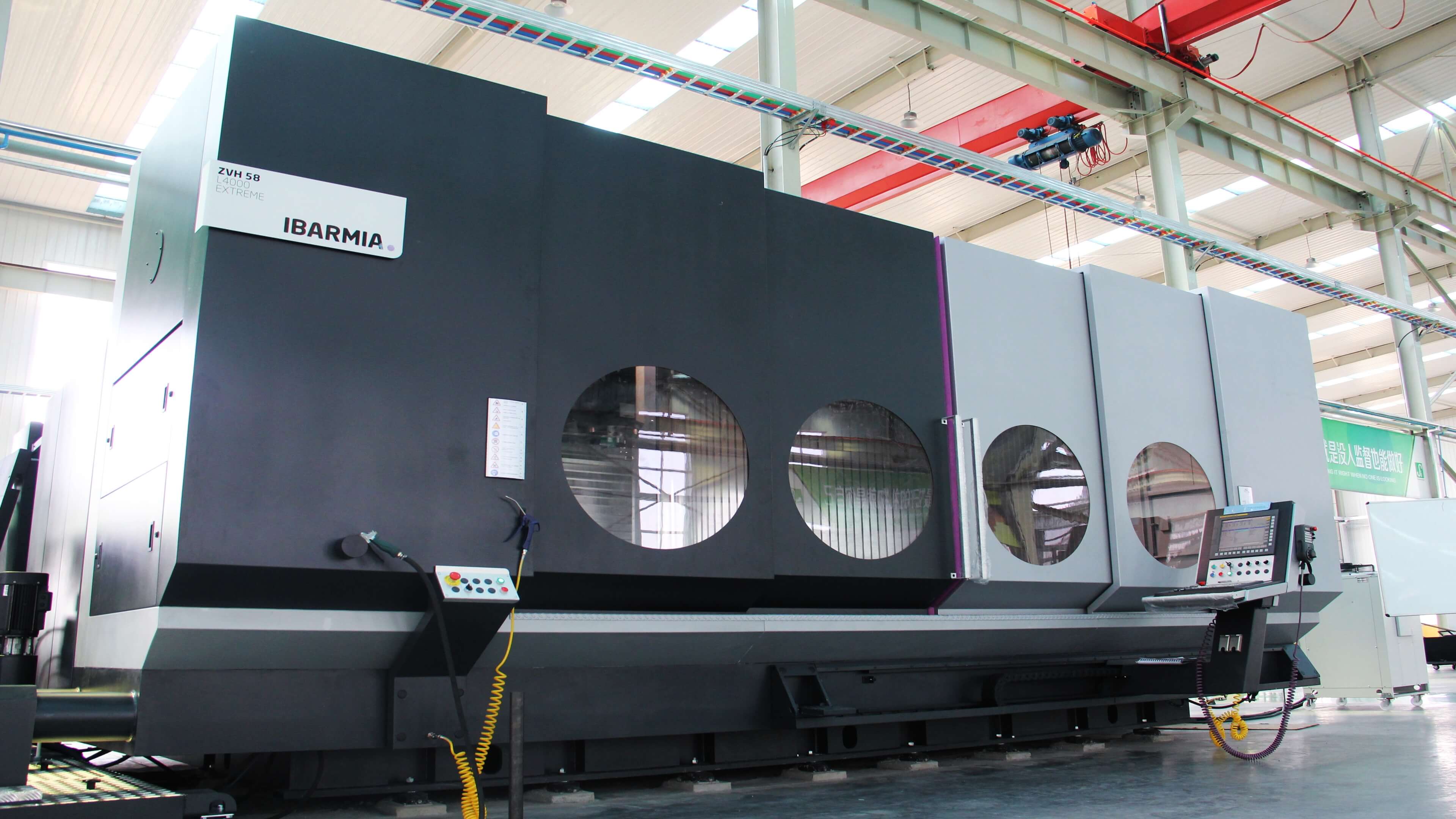

Machining—Advanced Machining Capabilities

Iraeta’s advanced machining capabilities are powered by a skilled team and cutting-edge equipment, enabling precision operations such as cutting, grinding, and drilling across a wide range of metal materials. By leveraging CNC technology, we efficiently produce intricate geometries with exceptional accuracy, ensuring every component aligns precisely with its design specifications.

Want to Know More About Our Capabilities?