Advanced Manufacturing for Extended Service Life

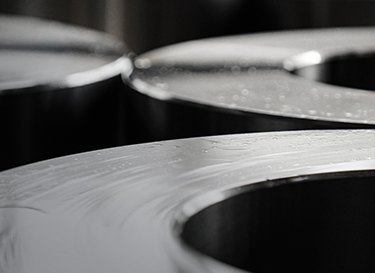

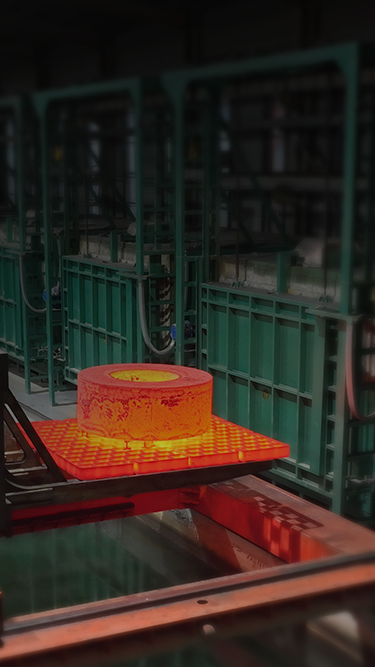

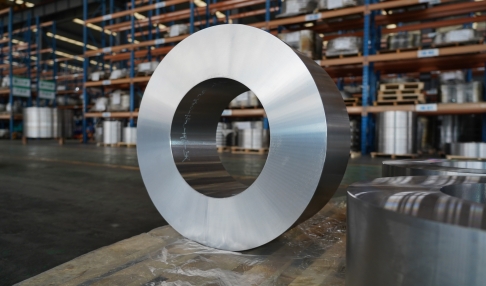

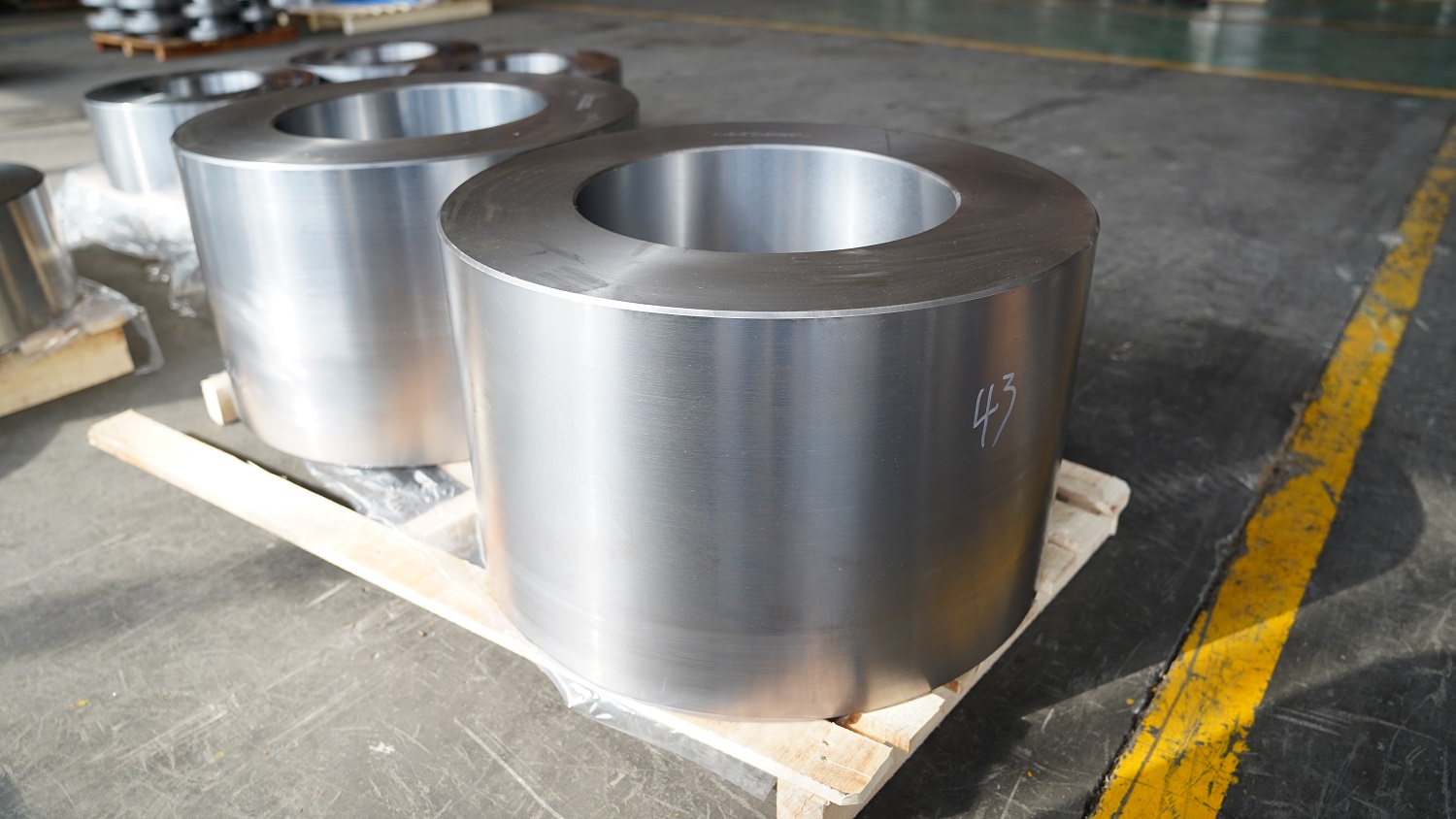

Gearbox forgings are precision transmission components requiring exceptionally stringent standards for raw materials, forging processes, heat treatment, and machining accuracy. To ensure long service life and high reliability in complex operating environments, we employ cutting-edge manufacturing techniques. Every parameter in the forging process is meticulously controlled, with rigorous attention to detail that could impact product quality.

Comprehensive Quality Control at Every Stage

Creating a highly stable procurement environment for our clients remains our primary objective. Central to this is our core strength: guaranteed product consistency. We implement a stringent quality management system throughout the entire production cycle - from raw material selection to final product inspection. Each gearbox forging undergoes multiple verification stages to ensure it exceeds industry standards, delivering premium quality products.

Dedicated R&D Team for Custom Solutions

Our specialized research team continually monitors technological advances in the industry and incorporates the latest material science and manufacturing innovations into product development. Whatever your unique requirements, we provide rapid response from design conception to delivery, offering bespoke solutions and comprehensive technical support.

Performance Showcases

Customer: Customers in Jiangsu

Quantity: 1,400 units per year

Customer: A certain customer in Hunan Province

Quantity: 850 units per year

Customer: A certain customer in Hangzhou

Quantity: 430 units per year

Business Inquiry

China projects:0531-83802699

China projects:0531-83809232

Or email us at ebiz@iraeta.com

Where Big Ideas Get Forged

We operate a world-class forging cluster, featuring exclusive mills that set us apart in the industry. These industrial powerhouses break through traditional manufacturing limits, empowering engineers to unleash their creativity and bring groundbreaking designs to life.

See Our Power

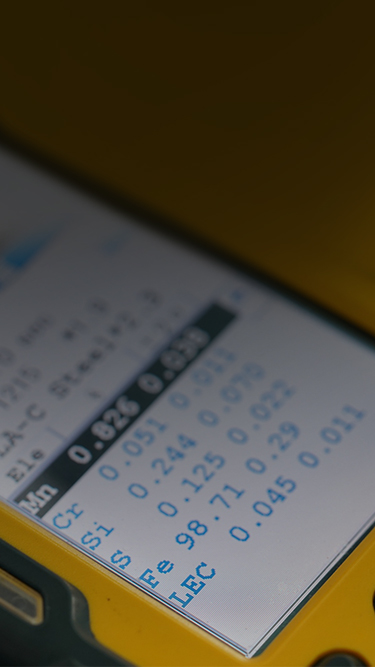

Green Steel

Most of our raw materials are sourced from our own short-process steel mills, where leftovers from production are recycled. This green cycle plays a crucial role in significantly reducing carbon emissions in our products.

What's Green Steel?