25MW! 12-Meter Diameter! Iraeta Achieves Another New Breakthrough in Offshore Wind Power Forgings

On July 14, 2025, the last batch of CSSC 25MW offshore wind power flanges were successfully shipped from Iraeta. The products delivered this time will be applied to CSSC 25MW offshore wind turbines.

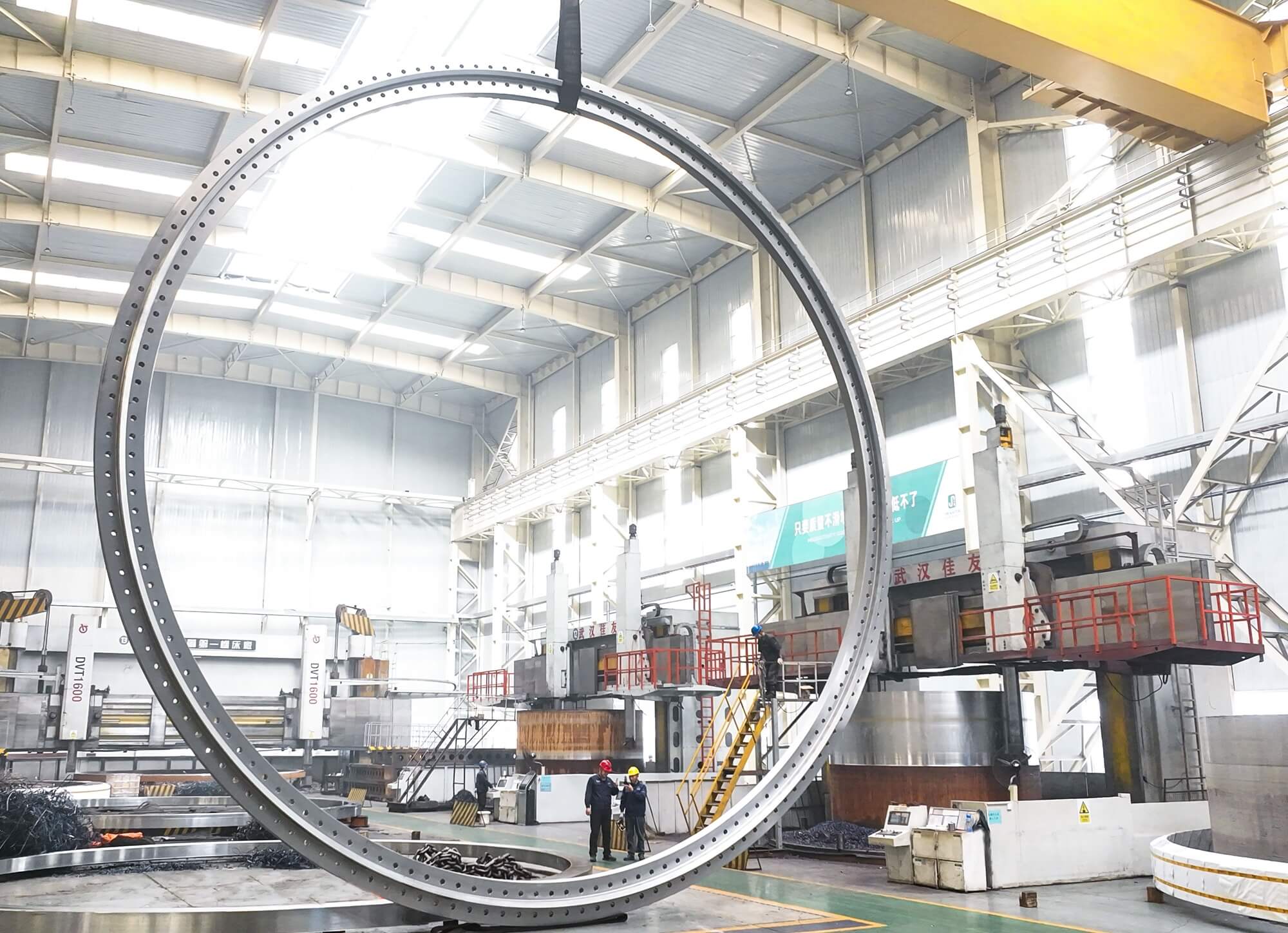

CSSC 25MW wind power flanges shipped from Iraeta

As a new generation of large offshore wind turbines custom-developed specifically for far-reaching offshore areas, this model covers a single-unit power range of 20-25MW, with a rotor diameter reaching 305 meters. It represents the advanced level of China's large offshore wind power equipment and provides strong support for the efficient development of far-reaching offshore wind power resources.

The project includes a total of 16 giant tower flanges, with the full set of products weighing 219 tons in total, among which the maximum single piece diameter is 12 meters. After the project was launched, Iraeta quickly coordinated and allocated resources, and successfully completed the product manufacturing by virtue of its accumulated advantages in equipment, technology and experience in the field of large offshore wind power ring forgings manufacturing.

Maximum diameter reaching 12 meters

Liang Zhen, Minister of the Second Trade Department of Iraeta's Sales Center, stated: "We have over 10 offshore wind power forging production lines worldwide, realizing full-chain closed-loop management from raw materials to flange finished product delivery, and have built the capability for batch and rapid delivery of large-diameter wind power flanges. The delivery of this 25MW flange is another test for us in terms of extra-large wind turbines. We are confident and capable of providing sufficient industrial support for various large offshore wind power projects."

Currently, in the global 15-25MW next-generation offshore wind power industry chain, Iraeta has successfully provided supporting components for giant wind turbines such as CRRC 20MW, Dongfang Electric 18MW, Goldwind 16MW, Shanghai Electric 16MW, and Vestas 15MW.

CRRC 20MW-class wind power flanges

As an important link in the global wind power industry chain, Iraeta has continued to make efforts in technological innovation and equipment upgrading in recent years. Iraeta has a self-built short-process steel plant, and through carbon reduction manufacturing technologies such as recycling forging industry scraps, hot delivery of raw materials, and oxygen-enriched combustion, it can help customers achieve low-carbon wind turbine manufacturing and low-carbon wind farm construction.

In terms of equipment upgrading, Iraeta launched the "Ultra-large Key Core Forging Components Project" last year. By introducing a cluster of equipment including a 22-meter super ring rolling mill, a 22,000-ton global largest free forging press, and a 22-meter extra-large diameter heavy vertical lathe, it has continuously broken manufacturing limits and can fully meet the ring forging needs of various clean energy equipment such as nuclear power, wind power, and hydropower in the future.

22,000-ton global largest free forging press

The delivery of this 25MW-class tower flange is a significant milestone for Iraeta in achieving another key progress in the offshore wind power field. Going forward, Iraeta will continue to increase R&D investment to provide higher-quality products and technical services for the innovative development of China's offshore wind power industry.

Recommended reading

Iraeta Supports France's First Floating Wind Power Forging Project

Deepen Cooperation and Forge Ahead Hand in Hand —— The Chairman of ACEK Group Pays a Visit to the Leaders of Jinan City and Visits Iraeta.

The Startup Ceremony of the First 12.83-meter Semi-autogenous Grinding Ball Testing Machine in China was Held at Iraeta.

12m Wind Tower Flange for 20MW Turbines Rolls Off Production Line at Iraeta.

A "Carbon Peak Reaching" Pacemaker! Iraeta Selected