Fully Rolled Structure for Higher Performance

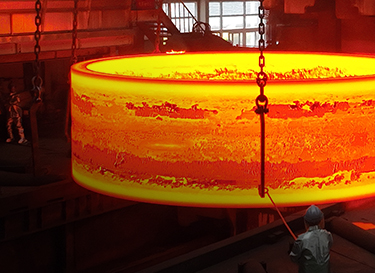

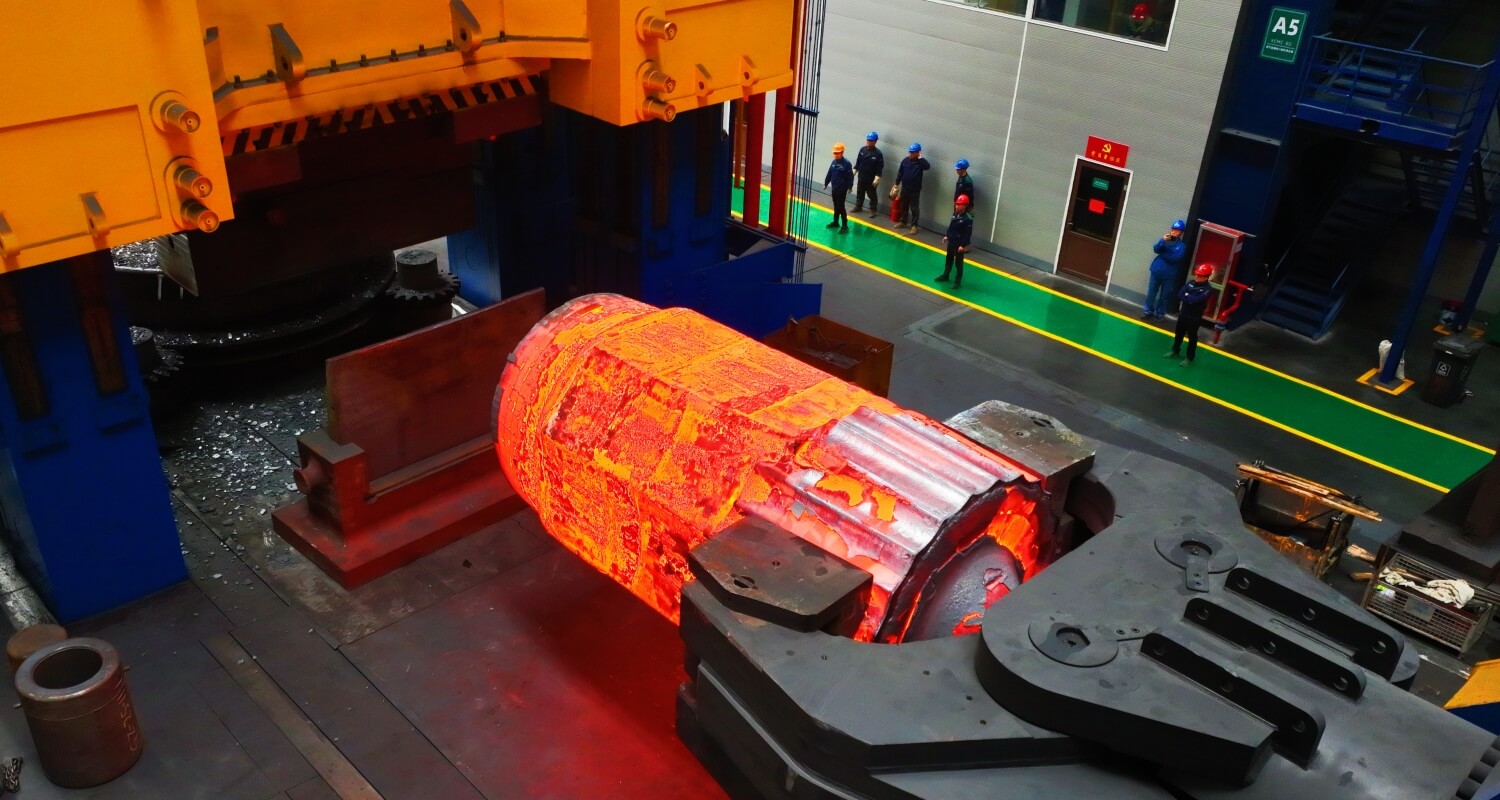

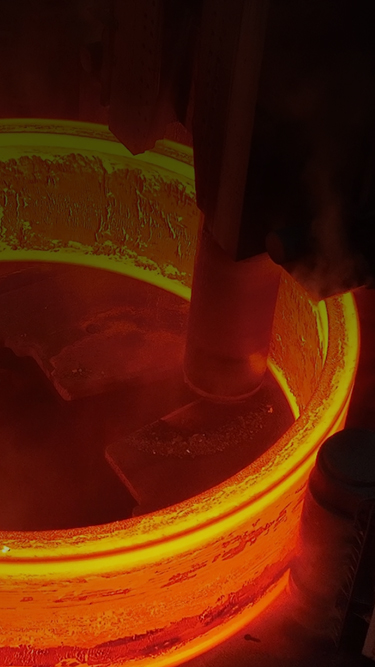

We use radial-axial full rolling to manufacture ultra-large hydropower forgings. This continuous forming process gives components such as magnetic yoke discs higher overall rigidity, significantly improving machining and installation accuracy—critical for generators that frequently start, stop, and switch between pumping and generating modes.

More Flexible Dimensions: The radial-axial rolling technology breaks through the limitations of traditional free forging press opening space on forging dimensions, enabling the production of extra-large forgings with a diameter exceeding 10 meters and a weight exceeding 300 tons. This has opened up new design ideas for many large pumped storage power plants in China.

Extensive Track Record Across Major Project

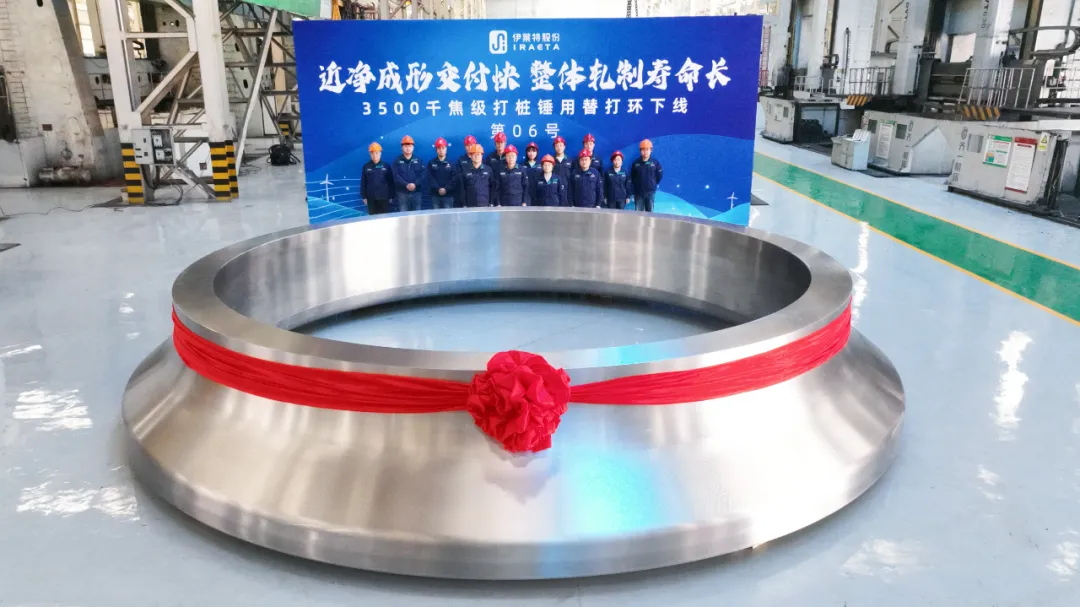

Iraeta has an extensive track record in the hydropower sector. Since 2019, we have supplied 26 one-piece yoke forgings for the Fengning Pumped Storage Project, which was then the world’s largest of its kind.

We have also delivered yoke discs, ring plates, mirror plates, top-cover flanges, center bodies, and other key forgings for multiple projects, including the Jinsha River Yinjiang units, Zhejiang Jinyun Pumped Storage, Heilongjiang Huanggou Pumped Storage, Guangdong Yangjiang Pumped Storage, and Guangxi Datengxia Hydropower Station.

These widely distributed projects demonstrate the reliable performance of our products across different hydropower units.

Customized for Each Project

We have supplied hundreds of hydropower forgings of various specifications to dozens of domestic and international power stations. Leveraging advanced equipment, extensive experience, and industry insight, we analyze each project’s specific conditions — such as head and installed capacity — to design tailored solutions for key components like large buckets, runners, guide rings, and lower rings. This ensures the stable operation of high-head, large-capacity units.

Performance Showcases

Project: Fengning Pumped - Storage Power Station

Type: Rotor Yoke Disk

Quantity: 18 pieces

Project: Jinsha River Yinjiang Tubular Turbine Unit

Product Type: Rotor Yoke Ring, Central Body

Quantity: 12 pieces

Project: Zhongdong Pumped - Storage Power Station in Huizhou, Guangdong

Product Type: Hydro - generator Rotor Yoke Forgings

Quantity: 20 pieces

Business Inquiry

Where Big Ideas Get Forged

We operate a world-class forging cluster, featuring exclusive mills that set us apart in the industry. These industrial powerhouses break through traditional manufacturing limits, empowering engineers to unleash their creativity and bring groundbreaking designs to life.

See Our Power

Green Steel

Most of our raw materials are sourced from our own short-process steel mills, where leftovers from production are recycled. This green cycle plays a crucial role in significantly reducing carbon emissions in our products.

What's Green Steel