Longer-Lasting “Forging-Rolling” Drive Rings

Drive rings are consumable forgings that must withstand enormous impact forces during pile-driving operations.

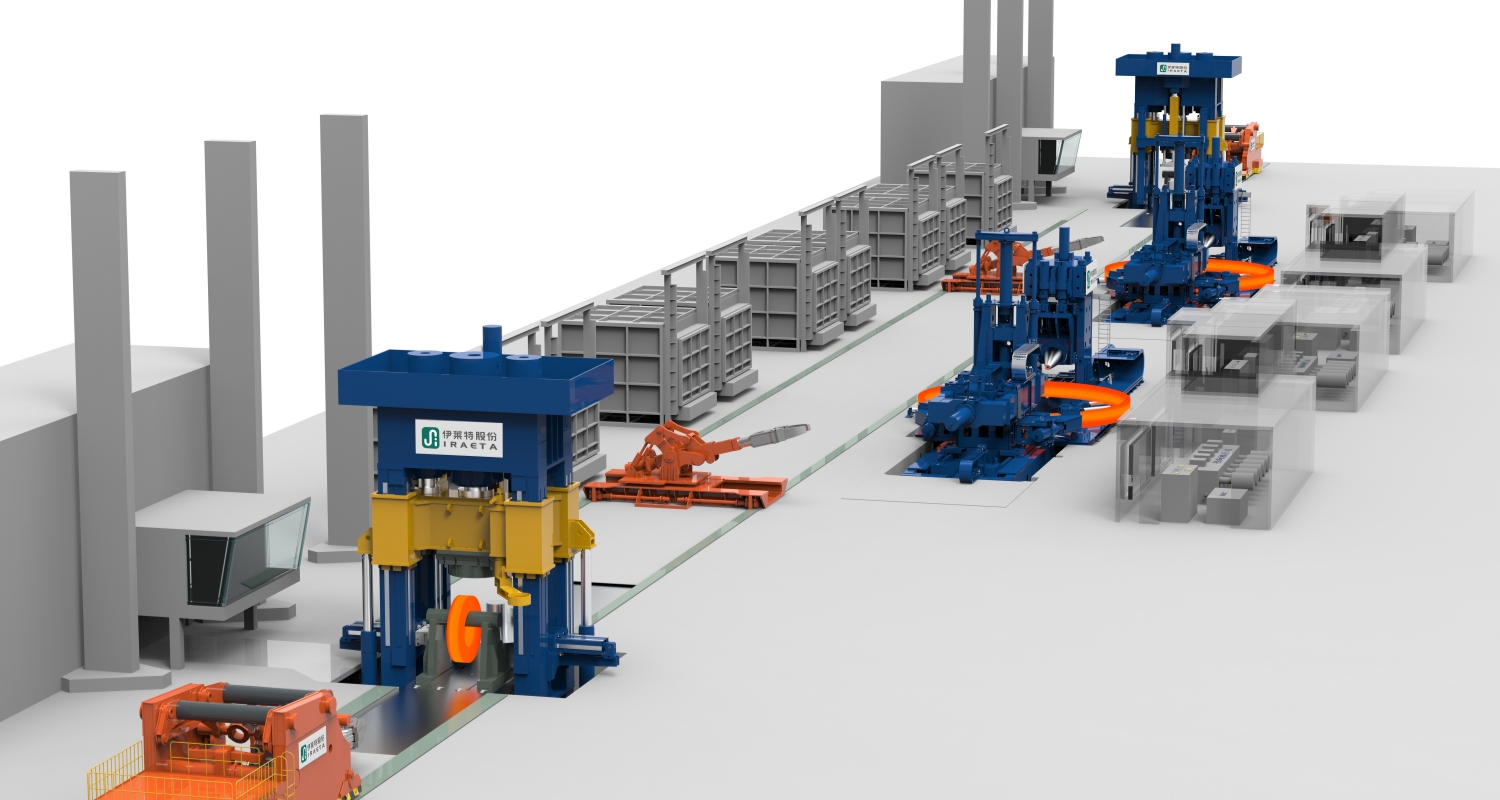

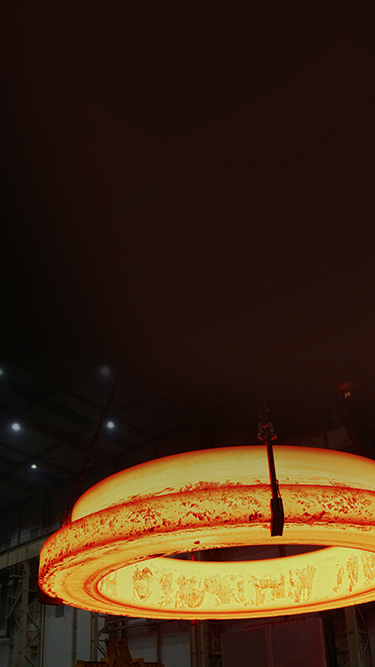

Unlike pure free forging, we use a “forging-rolling” process to manufacture drive rings. First, large-deformation multi-directional free forging breaks up coarse grains in the steel billet. Then, radial-axial rolling is applied for further forming. Radial-axial rolling is a continuous forming process, and under strong rolling forces, the metal fibers align with the circumferential direction of the workpiece, forming continuous flow lines. This enhances the impact resistance of the drive rings, extends their service life, and allows them to complete more pile-driving tasks.

More Cost-Effective Drive Rings

Compared with conventional free forging, the forging-rolling process requires fewer heating cycles and provides higher forming precision. This means we can not only complete manufacturing faster, but also reduce machining allowances and energy consumption, offering advantages in cost control and rapid delivery.

Ready for Larger Offshore Wind Turbines

Offshore wind turbines are growing bigger, with tower base flanges now over 12 meters in diameter. This calls for larger steel pile sections. Traditional free forging struggles to make extra-large drive rings because of press limitations, but our forging-rolling process can produce drive rings of almost any size without such restrictions.

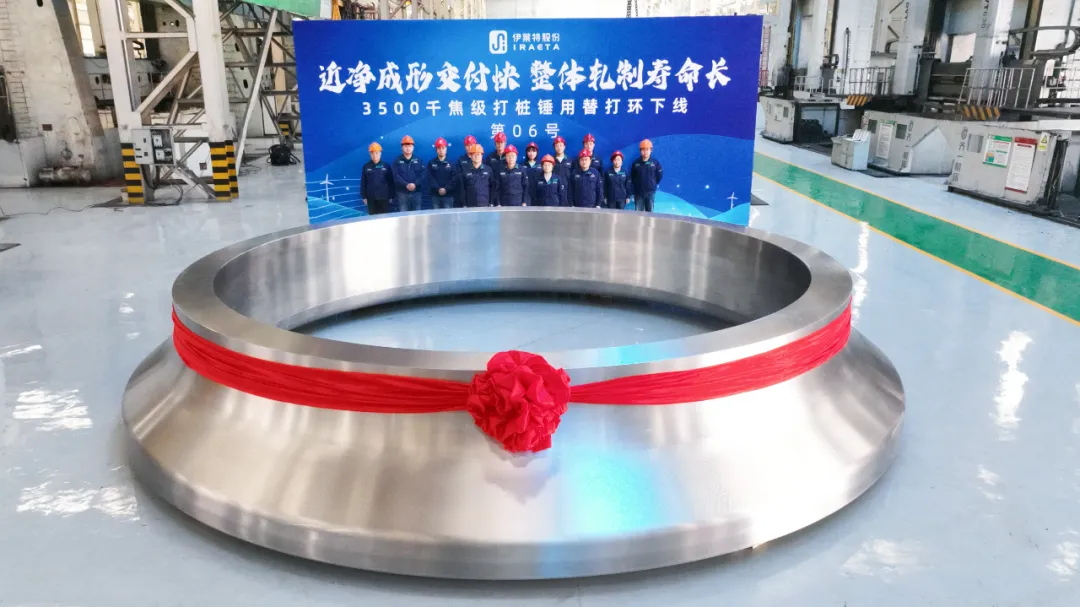

Performance Showcases

Customer: A Chinese client

Diameter: 7.5 meters

Height: 1.2 meters

Tonnage: 102 tons

Customer: Shanghai Electric SHMP Casting & Forging Co., Ltd.

Diameter: 7.6 meters

Height: 1.2 meters

Tonnage: 101 tons

Customer: TZ Binhai Heavy Machinery Co.,Ltd.

Diameter: 7.5 meters

Tonnage: 39 tons

Business Inquiry

Where Big Ideas Get Forged

We operate a world-class forging cluster, featuring exclusive mills that set us apart in the industry. These industrial powerhouses break through traditional manufacturing limits, empowering engineers to unleash their creativity and bring groundbreaking designs to life.

See Our Power

Green Steel

Most of our raw materials are sourced from our own short-process steel mills, where leftovers from production are recycled. This green cycle plays a crucial role in significantly reducing carbon emissions in our products.

What's Green Steel