12m Wind Tower Flange for 20MW Turbines Rolls Off Production Line at Iraeta.

On October 17, 14 smaller "Qiankun Rings"—the wind tower flanges manufactured by Iraeta for the world’s largest floating offshore wind units—were successfully dispatched. This milestone marks another key breakthrough for Iraeta in the offshore wind sector.

This set of products will be used in the world’s largest current floating offshore wind unit—the CRRC 20MW-class floating wind turbine.Each unit can generate 62 million kilowatt-hours (kWh) of electricity annually, equivalent to saving 25,000 tons of coal and reducing carbon dioxide (CO₂) emissions by 62,000 tons.

During operation, floating wind turbines are subjected to combined loads from wind, waves, and ocean currents, causing the structure to undergo complex motions including heave, sway, and surge movements. This dynamic operational environment imposes extremely stringent requirements on the stability of structural components such as flanges.

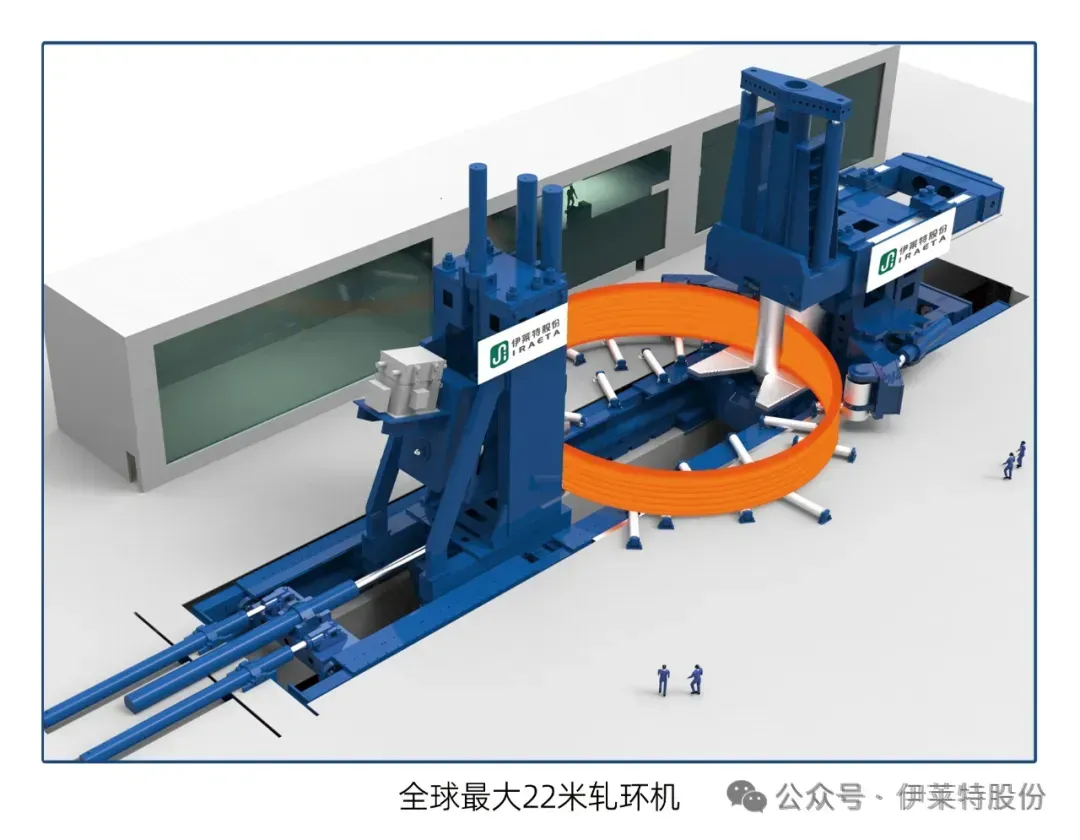

This project involves a total of 14 giant wind tower flanges, with an overall weight exceeding 240 tons. Eleven of these flanges have an outer diameter surpassing 10 meters, with the largest measuring 12 meters in diameter.

Upon project commencement, Iraeta mobilized its elite technical team, leveraging decades of accumulated advantages in equipment, engineering expertise, and manufacturing experience for large-scale offshore wind ring forgings.

By strictly controlling quality inspections at every production phase, the company successfully delivered the fully manufactured products in compliance with stringent specifications.

The delivery of this 12-meter-class tower flange represents not only a major milestone for Iraeta in the offshore wind sector but also a critical piece of the puzzle in China’s industrial chain collaboration and supply chain integration for next-generation 20MW+ offshore wind projects.

Recommended reading

25MW! 12-Meter Diameter! Iraeta Achieves Another New Breakthrough in Offshore Wind Power Forgings

Iraeta Supports France's First Floating Wind Power Forging Project

Deepen Cooperation and Forge Ahead Hand in Hand —— The Chairman of ACEK Group Pays a Visit to the Leaders of Jinan City and Visits Iraeta.

The Startup Ceremony of the First 12.83-meter Semi-autogenous Grinding Ball Testing Machine in China was Held at Iraeta.

A "Carbon Peak Reaching" Pacemaker! Iraeta Selected