Chairman's Speech

Welcome to Iraeta!

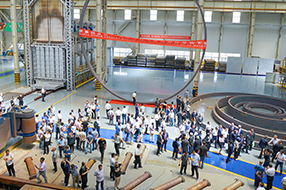

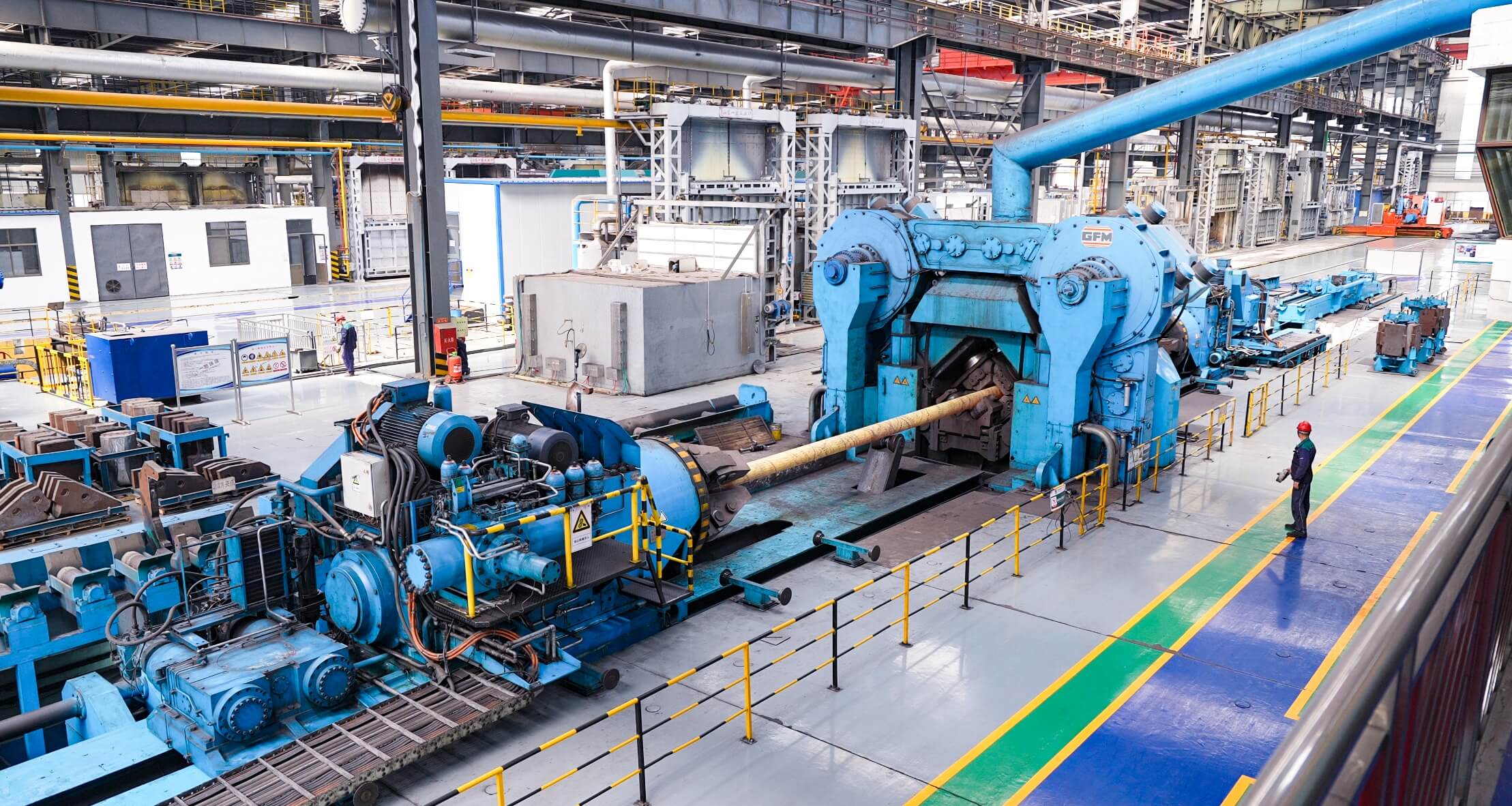

As a key global manufacturer of forged components, our products—crafted from a wide range of materials and available in various forms and performance levels—are actively contributing to major engineering projects around the world. These include 25 MW offshore wind turbines, 16-meter-diameter tunnel boring machines, and 700 MW concentrated solar power plants. Unlike these awe-inspiring structures that are visible to the eye, forging plays the unsung hero’s role. Hidden deep within, countless forgings must operate with flawless reliability—often for decades.

It is this increased reliability and stability that make us the preferred choice for our customers.

I entered the forging industry early in my career, and over the past 40 years, I’ve been fortunate to witness and contribute to numerous industry-defining innovations—whether in materials, processes, or pioneering equipment that pushes the boundaries of engineering. These experiences have only strengthened my belief: whenever humanity seeks to reshape the physical world or harness powerful natural forces—be it water, wind, nuclear energy, or even space—forging consistently provides dependable solutions with limitless potential.

Of course, our industry is currently facing unprecedented challenges, particularly the wave of ESG transformation. Thankfully, Iraeta has been proactive in exploring practical strategies—from decarbonized manufacturing and people-first workplace initiatives to strengthening our commitment to social responsibility. These efforts are helping us build a more resilient competitive edge, and we’re excited to share our journey with you—and eager to hear your thoughts along the way.

Niu Yugang, Chairman of Iraeta

Mission

To lead the world in critical forgings for advanced equipment

Vision

Forge a safer, greener, and more efficient future for all

Values

Honesty, Humility

Perseverance, Work

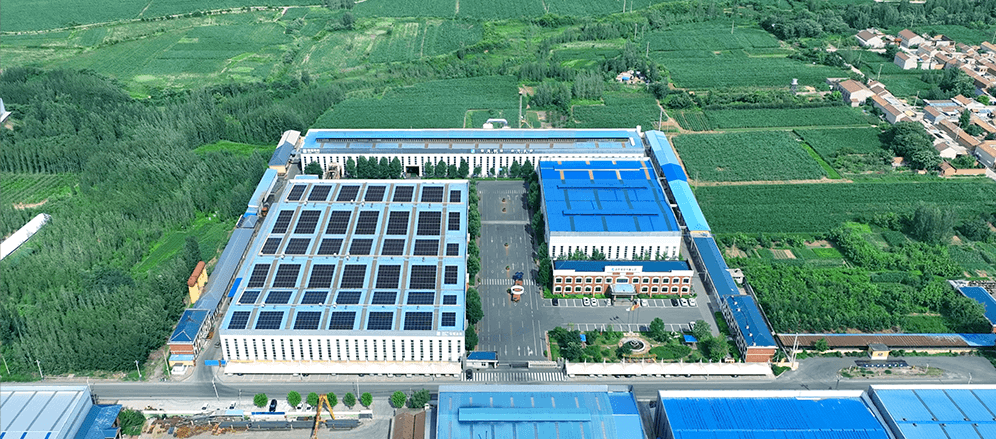

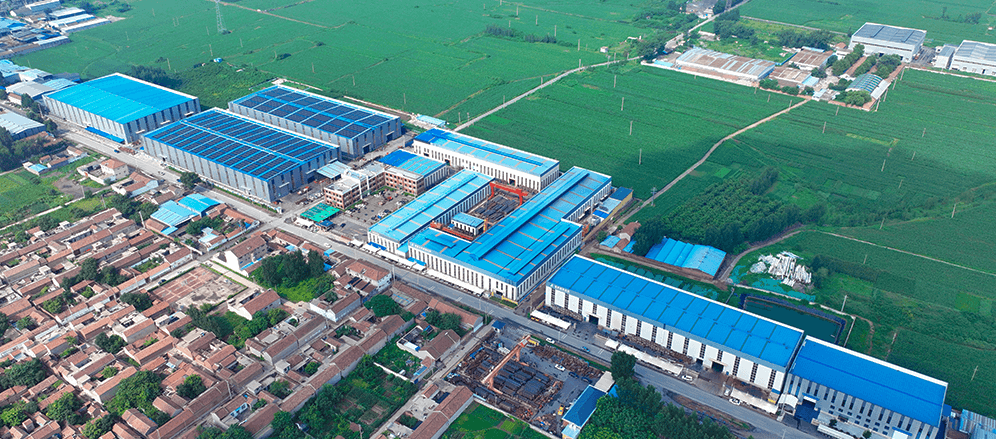

10 Manufacturing Bases in China and Spain

History

2006-2010

2011-2015

2016-2020

2021-2025

ESG: Doing Well by Doing Green

Forging sits at the upstream core of the industrial supply chain. At Iraeta, our commitment to ESG is more than a promise—it drives real, measurable impact across downstream procurement networks. We pursue low-carbon manufacturing through cutting-edge metallurgical innovation, while staying deeply rooted in social responsibility at every stage of our operations.

Explore More

Got questions? We'll get back to you within 24 hours.

Contact Us