Steadfast Implementation of the Innovation-Driven Development Strategy

To address the complex and diverse needs of customers across various industries, we have established the Advanced Materials Industry Research Institute, dedicated to the implementation and transformation of cutting-edge technologies and advanced achievements. Guided by our innovation-driven development strategy, our R&D team—comprising over 100 experts and application engineers—continuously pushes the boundaries of technology. We have secured multiple core proprietary intellectual property rights in product development and technical equipment R&D.

Industry Standards Drafted and Formulated

Global Industry and Regional Certifications

Utility and New-type Patents

Forging Industry Experience

Qualified suppliers of 40 + Fortune 500 companies

Leading Through Innovation

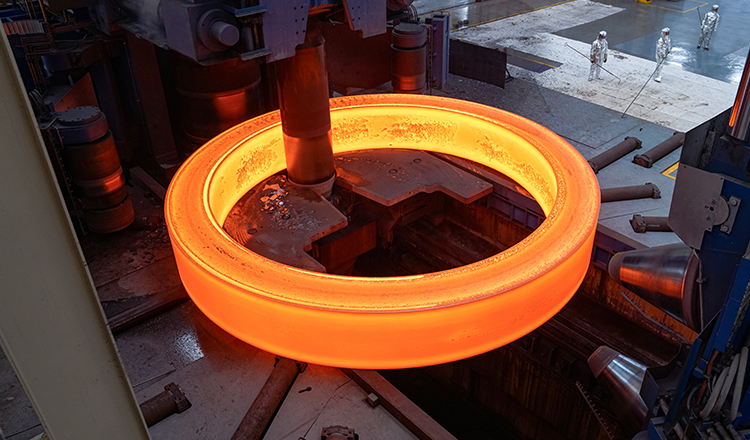

In 2019 and 2022, Iraeta achieved a global breakthrough by successfully applying two core technologies—metal construction forming and radial-axial ring rolling—to solve the world-class challenge of producing 150-ton-grade 316 stainless steel billets with exceptional purity and homogeneity. This technological milestone enabled us to deliver four 15.6-meter-diameter austenitic stainless steel seamless forged rings for China's fourth-generation nuclear power plants, setting new industry benchmarks.

More

Forging: A Superior Alternative to Casting

Rotary kilns are essential and critical equipment in the building materials and metallurgy industries, with riding rings being the most vital large-scale components. Compared to traditional cast riding rings, forged alternatives offer superior mechanical properties, enhanced durability, and reduced overall manufacturing costs. Since 2018, Iraeta has leveraged this technology to supply over a thousand forged riding rings to rotary kiln operators worldwide.

More

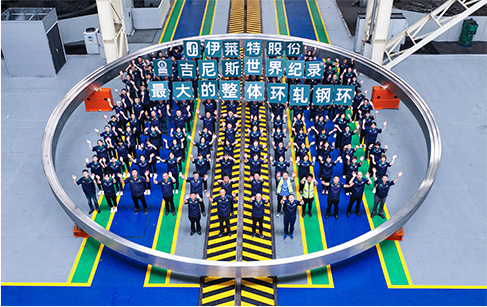

Dare to Dream, Dare to Achieve

Within every supply chain we engage, we are committed to becoming an indispensable long-term partner to our clients. To achieve this, we relentlessly pursue excellence, consistently delivering innovative materials and components across various industries, including nuclear power, wind energy, petrochemicals, and cement. Currently, the 22-meter super ring rolling mill project is underway, with us handling the manufacturing. Now, it's your turn to unleash your imagination!

Explore More

Cost Optimization

Our commitment to cost control goes far beyond conventional expectations. We deeply understand the critical impact that cost has on our clients' business operations. Every technological innovation and process optimization we implement aims to eliminate unnecessary complexities, enhance production efficiency, and deliver greater value to our clients at a lower cost.

Green Steel

Most of our raw materials come from self-built short-process steel mills, and the raw materials of the steel mills come from the recycling of leftovers during product processing. This green cycle can significantly reduce the carbon emissions of products.

What is green steel?

Want to Know More About Our Capabilities?