Hard Outside, Tough Inside

Slewing bearings must have highly consistent hardness and toughness around the circumference. Any flaw along the circumference can lead to stress concentration, cracks, or excessive wear. Bearing rings made by radial-axial rolling offer the following advantages:

More Complete Circumferential Flow Lines: Radial-axial rolling is a continuous rotary process. Under the strong force of the rollers, metal fibers flow along the circumference of the ring, forming closed circular flow lines that perfectly match the geometry of the slewing bearing.

Optimized Surface Hardness and Core Toughness: The ring surface, directly pressed by the rollers, has dense metal fibers aligned with the surface, while the core metal spreads outward under radial compression. This “dense surface – divergent core” gradient structure increases surface hardness while retaining core toughness, almost perfectly meeting the demands of large slewing bearings.

For Split-Type Slewing Bearings, Is It Necessary To Use One-Piece Bearing Rings?

Yes!!!!!!

Large-diameter split-type slewing bearings are often used in high-value offshore projects and need to withstand heavy radial, axial, and tilting loads, so high reliability is essential.

Traditionally, split-type bearings are made from several arc-shaped forgings. Each forging is produced, heat-treated, and machined separately, making it hard to ensure consistent performance. The process is also complicated and time-consuming.

Iraeta can produce one-piece bearing rings up to 22 meters in diameter. Thanks to integrated forming, heat treatment, and machining, these rings offer better consistency and performance, whether used as a whole or cut into segments for split-type bearings.

Performance Showcase

Customer: LYC

Diameter: 13.8 meters

Weight: 38 tons

Customer: China Railway Construction Heavy Industry Co., Ltd.

Quantity: 4 pieces

Diameter: 7.6 meters

Customer: Nantong Rainbow Heavy Machineries Co.,Ltd.

Quantity: 2 pieces

Maximum diameter: 15.01 meters

Business Inquiry

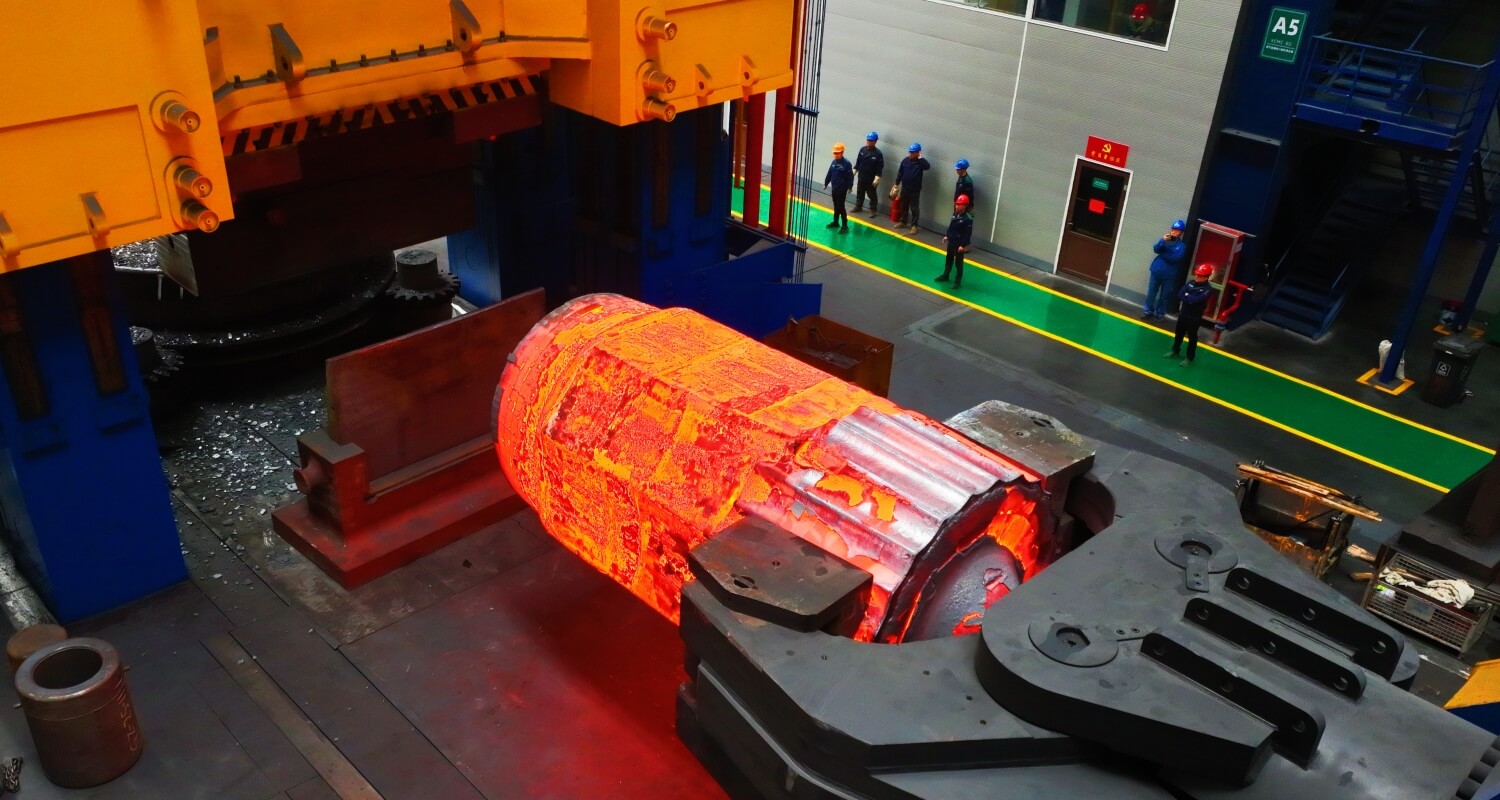

Where Big Ideas Get Forged

We operate a world-class forging cluster, featuring exclusive mills that set us apart in the industry. These industrial powerhouses break through traditional manufacturing limits, empowering engineers to unleash their creativity and bring groundbreaking designs to life.

See Our Power

Green Steel

Most of our raw materials are sourced from our own short-process steel mills, where leftovers from production are recycled. This green cycle plays a crucial role in significantly reducing carbon emissions in our products.

What's Green Steel