We Are a Vital Link in the Global Clean Energy Supply Chain

The majority of Iraeta's products are used across clean energy sectors such as wind, hydro, solar thermal, and nuclear power. As a key contributor to the global clean energy supply chain, we are deeply committed to lowering our own carbon footprint. In addition to using short-process steel as our primary raw material, we’ve adopted a range of low-carbon manufacturing solutions throughout our operations. These include hot charging of billets, oxy-fuel combustion, metal construction techniques, and near-net-shape forming.

Cutting Carbon with Advanced Manufacturing

Construction Molding

For certain alloys exceeding 100 tons, the utilization rate of conventional steel ingots drops to around 70%. Unlike molten steel casting, our metal construction forming technology uses smaller, high-quality steel billets. Through vacuum encapsulation and high-temperature diffusion bonding processes, we achieve “building big from small”, with a remarkable utilization rate of over 95%. This approach not only enhances quality but also significantly reduces carbon emissions from steelmaking and eliminates energy waste from heating non-productive materials.

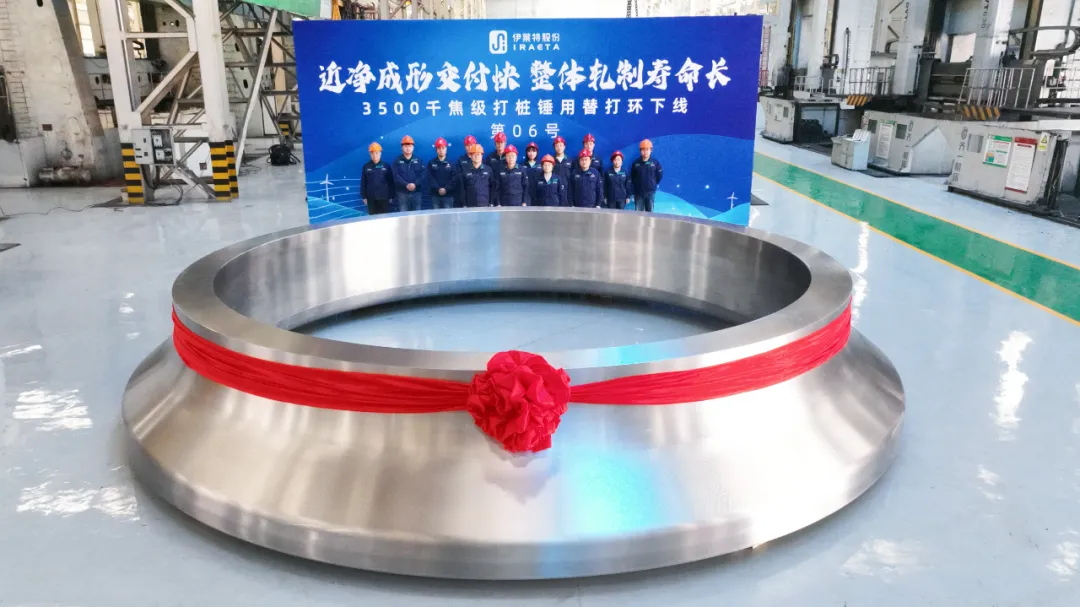

Near-Net-Shape Forming

The steel used for large forgings can range from tens of tons to hundreds of tons. Near-net shaping technology utilizes specialized designs to closely match the finished forging size, minimizing machining allowances and, in turn, reducing raw material use and carbon emissions from heating. Some products can even cut raw material consumption by up to 30%, resulting in substantial savings on your procurement costs!

Comprehensive Waste Management

Safeguarding the Atmosphere

We strictly comply with all applicable environmental regulations, employing advanced systems such as SCR denitrification, pulse-jet baghouse filters, and continuous emissions monitoring (CEMS) to ensure rigorous control of exhaust treatment and full compliance with emission standards.

Maximizing Waste Recycling

We have implemented a comprehensive recycling process for steel scrap and residual materials generated during production, aiming to recover valuable raw materials and achieve both environmental sustainability and resource efficiency.

Cutting Carbon in Energy Use

Oxy-Fuel Combustion

Ambient air contains approximately 21% oxygen. Our oxy-fuel combustion technology increases oxygen concentration, improving furnace efficiency while reducing NOx emissions.

Rooftop Photovoltaic Systems

We've installed 26 MW of rooftop solar capacity across our main facilities, generating over 20 million kWh annually. This fully covers all our office and HVAC electricity needs, as well as a portion of our production power requirements.

Relevant News

Explore More