Which Metals Are Best for Forging?

Forged components are widely valued in industry for their excellent strength, toughness, and impact resistance. However, their final performance is not determined by the manufacturing process alone — the choice of material also plays a key role. In fact, almost any metal can be forged. This article focuses on the four most commonly used forging materials at Iraeta — carbon steel, alloy steel, stainless steel, and aluminum alloy — and explains their properties and how to select them.

Carbon Steel

Carbon steel, also called plain carbon steel, is an iron-carbon alloy with less than 2% carbon. Besides carbon, it contains small amounts of silicon, manganese, sulfur, and phosphorus. Its performance depends directly on carbon content and can be divided into low-carbon steel (≤0.25%), medium-carbon steel (0.25–0.6%), and high-carbon steel (>0.6%). Higher carbon content increases strength and hardness but reduces ductility and toughness.

With high strength, good ductility, and easy machinability, carbon steel is widely used across industries. Common grades include Q235B, Q345R, 20#, 16G, A106, and A333 Gr.6.

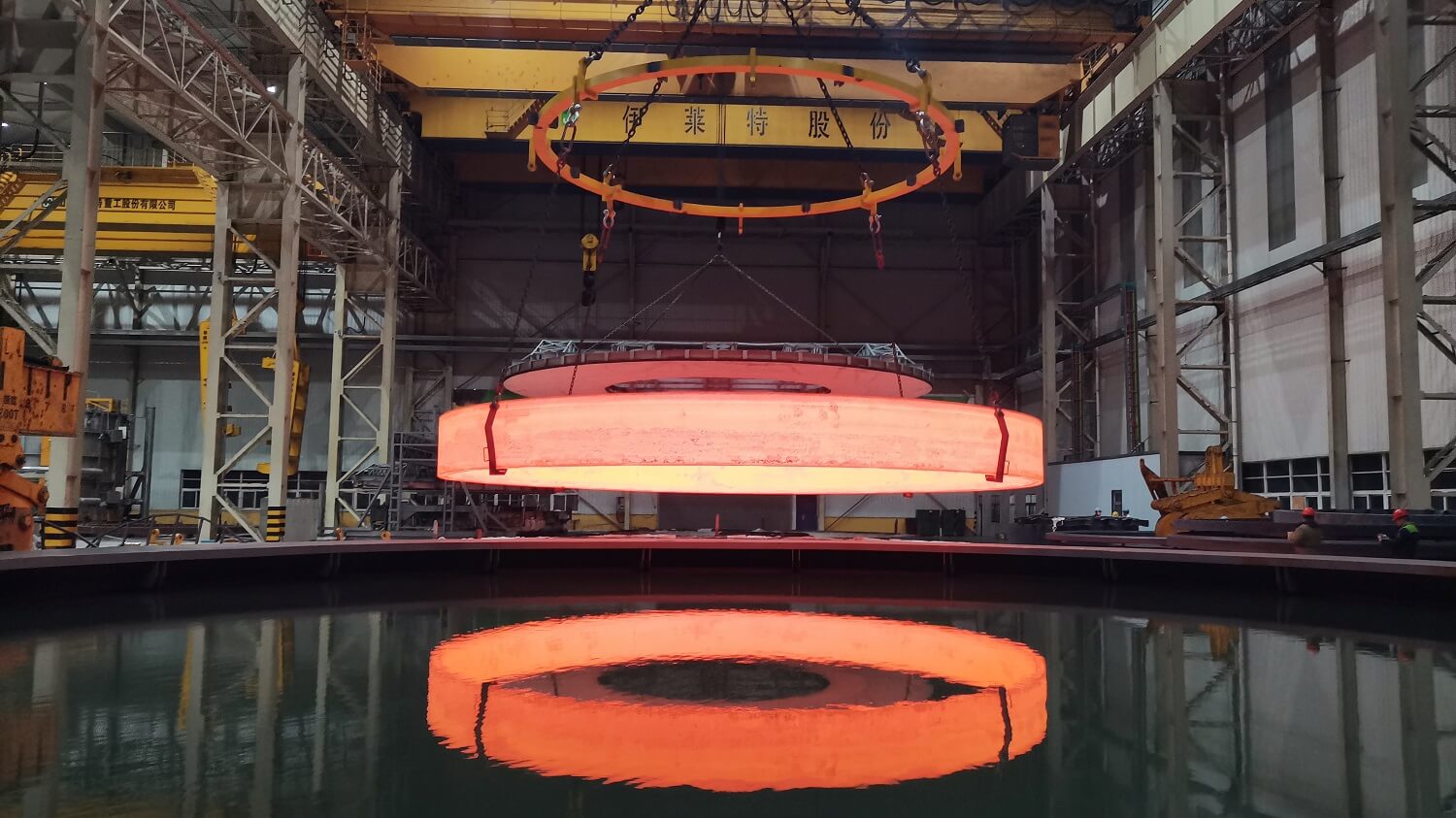

Wind power forgings made from carbon steel

Alloy Steel

Alloy steel is carbon steel with added elements like Cr, Ni, Mo, and V to improve strength, hardness, corrosion resistance, or high-temperature performance. It can be divided into low, medium, and high alloy steel depending on composition and purpose. Different elements bring different benefits:

Aluminum: Refines grains, stabilizes nitrogen, improves impact toughness and corrosion resistance, especially when combined with Mo, Cu, Si, or Cr.

Nickel: Significantly increases strength while maintaining high toughness.

Copper: Enhances resistance to atmospheric corrosion; combined with phosphorus, it also increases strength and yield ratio without affecting weldability.

In short, alloy steel can be tailored to meet a wide range of requirements by adjusting its composition.

A 12-meter titanium alloy forged ring

Stainless Steel

Stainless steel is technically a type of high-alloy steel but is often treated separately due to its unique properties. Its main feature is corrosion resistance, allowing it to withstand air, moisture, and mild corrosive environments. This is mainly due to chromium: when Cr ≥10.5%, a thin, dense chromium oxide layer forms, providing self-protection.

Based on microstructure, stainless steel can be classified as:

Ferritic: 10.5–18% Cr, low Ni, cost-effective (e.g., 430, 446).

Martensitic: Hardenable, used for precise, hardened edges (e.g., 410, 420, 440).

Austenitic: Most common, ≥16% Cr and 6% Ni (200, 300 series).

Duplex: Mix of austenite and ferrite, balancing weight, toughness, and strength.

Precipitation-hardening: Strengthened by aging treatment.Forging can further enhance stainless steel, making it ideal for high-temperature, high-stress, and corrosive environments.

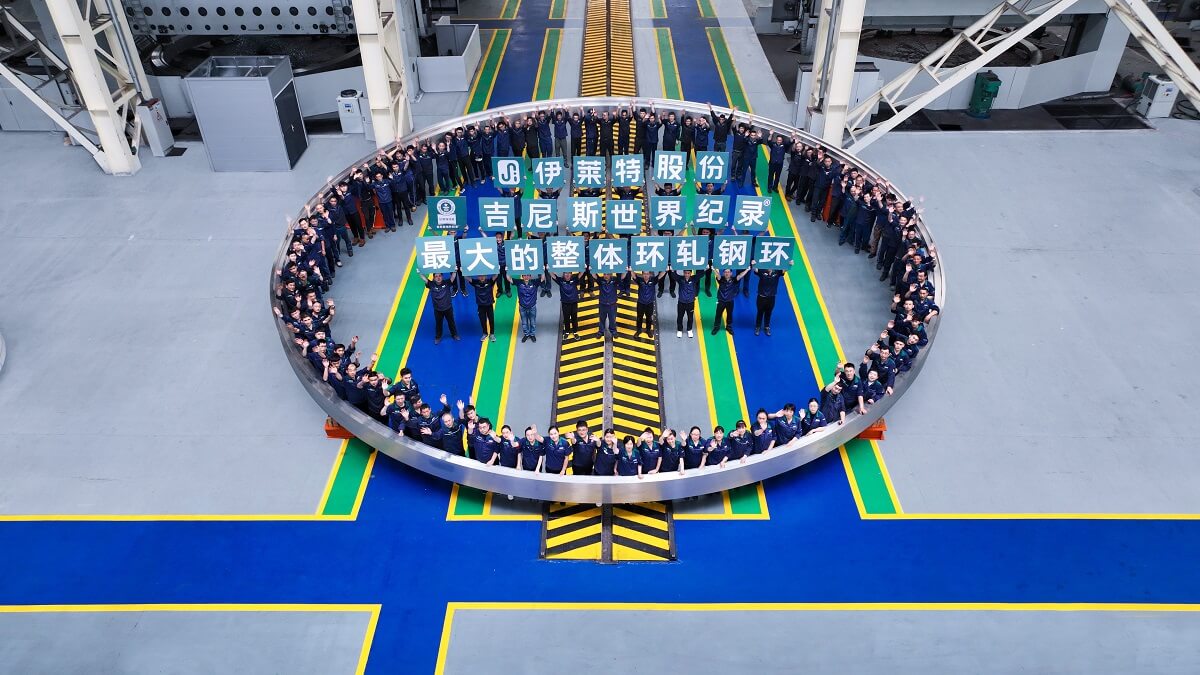

A 15.673-meter austenitic stainless steel forged ring

Aluminum Alloy

Aluminum alloys are widely used lightweight metals in aerospace, shipbuilding, and machinery. Their main advantage is the combination of lightweight and strength.

Aluminum serves as the base, with Mg, Si, Cu, Zn, and other elements added to improve strength, hardness, and corrosion resistance while keeping density low. Applications include:

Aerospace: Aircraft structures and engine parts to reduce weight.

Automotive & rail: Lightweight wheels and chassis parts to improve efficiency.

Machinery: Replacing steel components to reduce overall equipment weight.

Aluminum alloy forged rings produced by Iraeta

How to Choose the Right Material

To select forging material, focus on three key points:

Usage and environment: Will the part face high temperature, heavy loads, moisture, or corrosion?

Forging suitability: Different materials require different forging methods; ensure material and process match.

Material + process synergy: Material provides the foundation; forging alters internal structure. Final performance is determined by both.

Understanding material properties is the first step to precise selection. Real-world applications can be more complex, depending on part conditions and process requirements. If you’re looking for the right forging material or want more detailed forging solutions, feel free to contact Iraeta.

Recommended reading

Unlocking the Secrets of Forging: The Performance Code of Classic Processes

Must-Read for Ring Forging: Advantages and Applications of the Forge-Rolling Process

Open-Die Forging vs. Ring Rolling: Helping You Choose the Optimal Forging Process

Unlocking Heat Treatment: How to Make Forgings Stronger, Tougher, and More Reliable

Forging Procurement: Manufacturer Or Middleman?