Project Background: As a core component supporting the rotation of heavy-duty rotary equipment such as cement kilns, the performance of the ring directly affects the stable operation of the entire system. For a long time, this critical part has mainly relied on casting processes. In 2019, Iraeta pioneered the “Forging Instead of Casting” solution, successfully delivering a forged ring with a diameter of 7.6 meters and a total billet weight of 170 tons to ThyssenKrupp, the century-old German industrial giant. This ring is now in service in a Turkish cement rotary kiln with a daily output of tens of thousands of tons.

Challenge 1: Inherent Issues of Cast Rings

Cast rings inevitably suffer from a variety of defects such as gas porosity, shrinkage cavities, slag inclusions, cracks, cold shuts, sand holes, non-metallic inclusions, coarse grains, and segregation. These defects cause uneven hardness and localized stress concentration, leading to cracks and frequent equipment downtime for maintenance. This poses significant losses to industries like cement and paper manufacturing, where continuous, automated, and enclosed operations are essential.

Challenge 2: Forming Difficulties of Extra-Large Billets

To avoid the defects inherent in cast rings, some engineers have shifted to another approach: using large mold-cast steel ingots as raw materials, then shaping them through conventional open-die forging.

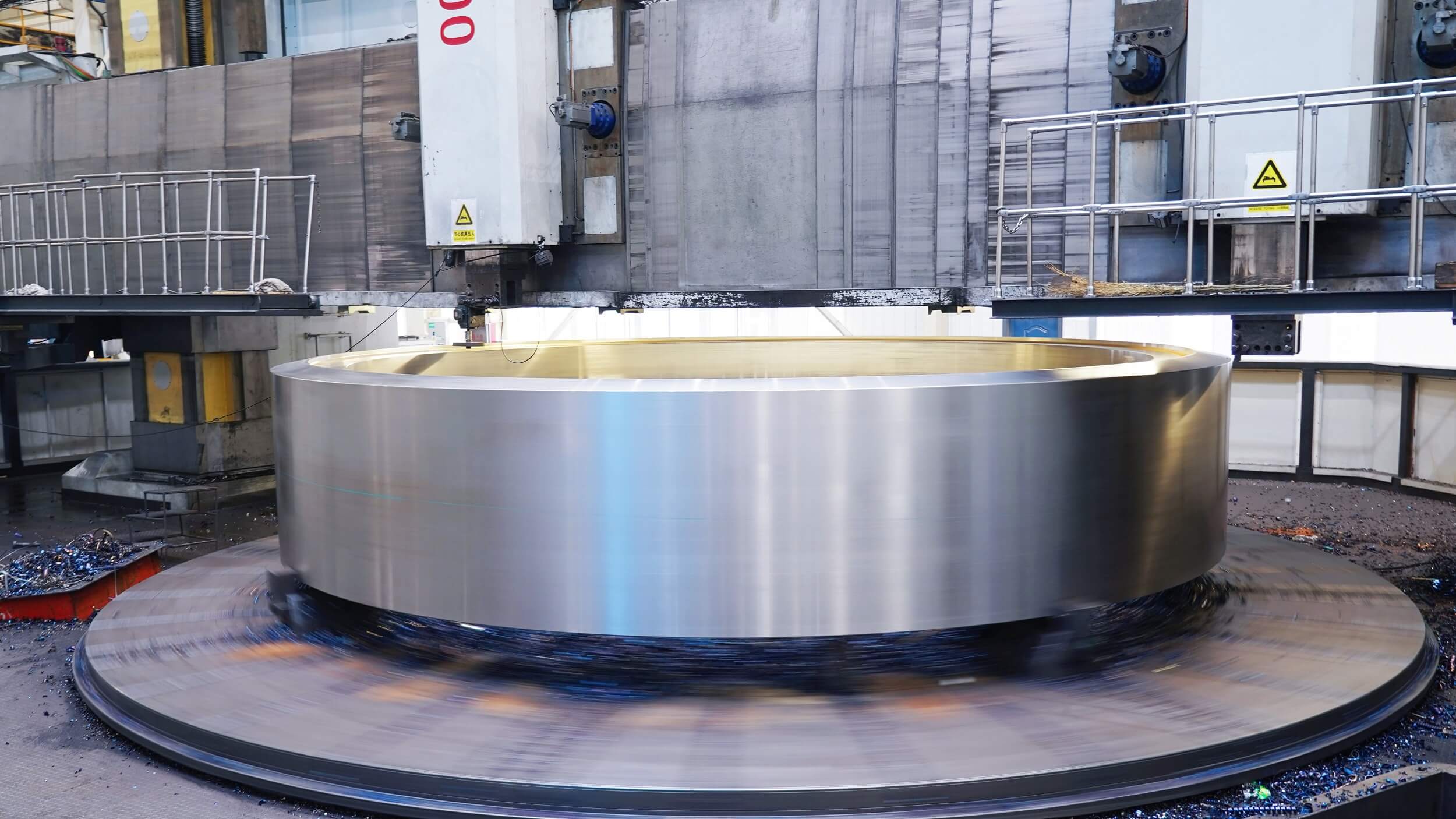

However, the ring in this project measures 7.6 meters in diameter, 1.5 meters in height, with a forging billet weighing over 170 tons. If traditional mold-cast steel ingots were used, the ingot weight would need to exceed 250 tons. Such massive ingots themselves suffer from composition segregation, internal shrinkage cavities, and inclusions, all of which affect hardness uniformity and service life. More importantly, even with open-die forging, processing steel ingots of this size approaches the manufacturing limits of China’s open-die forging presses, making it highly challenging technically.

Challenge 3: Heat Treatment

The heat treatment of ultra-large, ultra-high-performance rings is also extremely demanding. As the “load-bearing core” of cement rotary kilns, the ring must meet strict standards for surface hardness uniformity and core toughness, further complicating the heat treatment process.

Our Solution:

In response to these challenges, Iraeta’s technical team conducted extensive analysis and heat treatment breakthroughs, ultimately delivering a comprehensive “Forging Instead of Casting” solution for large rings.

Our approach combines “integrated rolling + near-net-shape forming” technologies, achieving a leap in performance through key process steps:

Step 1: We operate our own short-process steel mill, allowing us to precisely optimize the alloy composition and steel cleanliness of the raw materials used for the rings. For even higher standards, we can also utilize nuclear-grade raw materials.

Step 2: Our 13,500-ton press applies large-deformation, multi-directional forging that breaks down coarse casting grains inside the billet and reduces or eliminates internal porosity and looseness, significantly enhancing the ring’s density.

Step 3: A 16-meter ring rolling machine exerts powerful rolling forces simultaneously in both radial and axial directions, creating continuous fiber flow lines along the ring’s circumference. This further improves density and mechanical properties.

Step 4: Performance is further improved through a heat treatment process combining normalizing and quenching & tempering. Normalizing prepares the ring for heat treatment, followed by rough machining, then quenching and tempering.

Step 5: After machining, each ring undergoes rigorous flaw detection and performance testing to ensure it meets or exceeds design and industry standards.

Since launching our forged rings, Iraeta has quickly earned the favor of leading rotary kiln manufacturers at home and abroad. Since 2018, we have supplied thousands of forged rings to kiln owners worldwide.