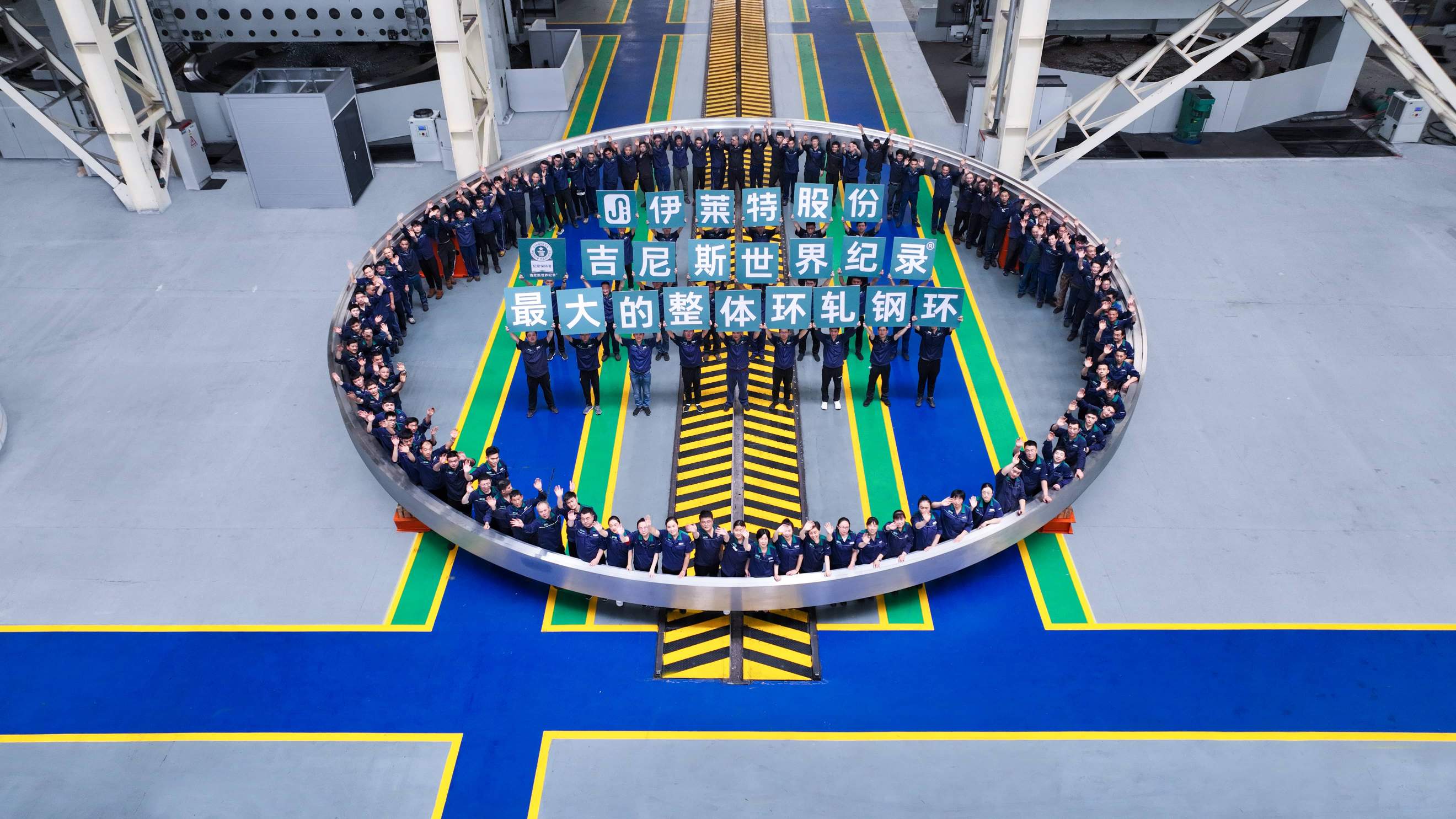

Project Background:In August 2022, Iraeta set a new Guinness World Record by successfully forging a one-piece support ring for China’s fourth-generation nuclear power unit. As the “backbone” of the reactor, this support ring is designed to carry the 7,000-ton reactor pressure vessel and remain in service for over 60 years without the possibility of replacement.Every process step must therefore meet the strictest standards to ensure both long-term safety and performance.

Challenge 1: Traditional Ingots Couldn’t Meet Material Requirements

Conventional forging of ultra-large components follows the principle of “big ingot for big part,” meaning the initial ingot must be significantly larger than the finished product. Based on this method, the required forging would have demanded a single 250-ton ingot. However, as ingot size increases, the likelihood of uneven alloy distribution during cooling and solidification rises significantly. This leads to localized mechanical property deviations, making it difficult to meet the high homogeneity standards required for nuclear-grade components.

Challenge 2: Welding Introduces Long-Term Safety Risks

Internationally, large rings of this type are often produced using a “segmented + welded” approach—fabricating 6 to 8 arc-shaped sections and welding them into a full ring. But welding naturally creates a structural weak point: the welded area retains a cast microstructure, with significantly lower strength, toughness, and corrosion resistance compared to a monolithic forging. In a nuclear power application, decades of heavy load and radiation exposure can lead to stress concentration at weld seams, increasing the risk of long-term failure and compromising reactor safety.

Challenge 3: Extreme Size Creates Heat Treatment Risk

With a diameter of 15.6 meters, the support ring qualifies as an ultra-large forging. During heating, soaking, and cooling, uneven temperature distribution becomes a major issue—often resulting in distortion.Any deformation during heat treatment may compromise dimensional accuracy, introduce internal stress, and reduce load capacity, ultimately disqualifying the part from nuclear installation standards.

Our Solution: In response to these challenges, Iraeta collaborated with the team led by Academician Li Yiyi of the Institute of Metal Research, Chinese Academy of Sciences. Together, we applied three core innovations to make the impossible possible.

● Material Preparation

Instead of conventional steelmaking, Iraeta used the “metal build-up + additive forming” technology pioneered by Li Yiyi’s team. Dozens of small austenitic stainless steel billets, each weighing only 4 tons, were stacked like bricks in a vacuum environment and sealed together. Through repeated high-temperature deformation—like kneading dough—the interlayer interfaces fused completely, producing a homogeneous large-scale steel billet with evenly distributed alloy elements.

● Forming Process

Iraeta used a “one-piece rolling + near-net forming” approach. With our 16-meter SMS ring rolling machine from Germany, we rolled the billet into a 15.673-meter-diameter ring in a single pass—without a single weld seam along its 50-meter circumference. This method ensured consistent strength, toughness, and corrosion resistance throughout the ring, eliminating all safety concerns associated with welding.

● Heat Treatment

To address heat treatment deformation, we developed a dedicated quench tank system and custom lifting fixtures. Precise furnace temperature control ensured thermal uniformity during heating. During cooling, zoned speed control was applied to minimize internal temperature gradients. Our symmetric lifting tools prevented ring deformation while the metal was in a soft, heated state.

As the world accelerates toward clean energy, nuclear power has never faced higher demands for safety and reliability. Iraeta’s breakthroughs in nuclear-grade forging raise the bar in material uniformity, structural safety, and dimensional stability—delivering stronger, safer solutions for a low-carbon future.

In 2019 and 2022, Iraeta successfully delivered four 15.6-meter austenitic stainless steel integral forged rings to China’s fourth-generation nuclear program. Currently, Iraeta is working with Tsinghua University on high-temperature gas-cooled reactor pressure vessel shells, and is in technical discussions with designers of the thorium-based molten salt reactor.