Project Background:With the rapid development of the global offshore wind power industry, the demand for high-performance marine construction equipment continues to grow. In particular, the cushion ring—a core energy transfer component in large hydraulic piling hammers—directly affects the efficiency and stability of piling operations. To meet the increasing demands of high-intensity operations and harsh marine environments, the industry is seeking large-diameter cushion rings that offer high impact resistance, strength, and uniform mechanical properties.

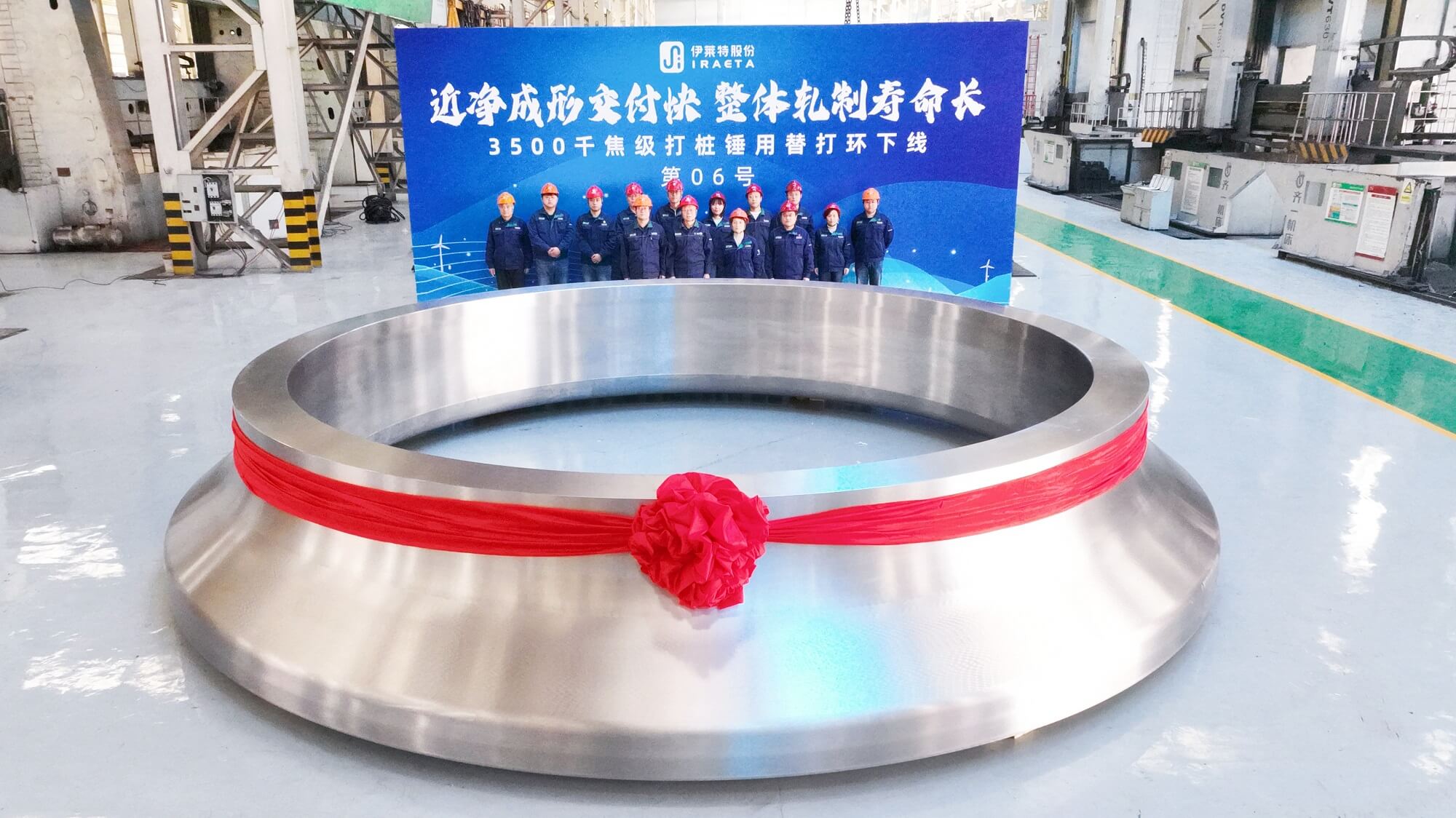

In this context, Iraeta successfully produced a 7.6-meter-diameter heavy-duty cushion ring, designed for use in a 3,500 kJ hydraulic piling hammer.

Challenge 1: Harsh Operating Conditions with High-Intensity Cyclic Impact Loads

In monopile foundation construction for offshore wind farms, the cushion ring acts as the core energy transfer interface in a massive hydraulic piling hammer. It is responsible for accurately delivering immense impact energy to the steel pile, ensuring the 2,000+ ton pipe is firmly driven into the seabed—laying a solid foundation for turbine installation.

Each impact on the cushion ring is equivalent to the energy of a dump truck falling from a height of 100 meters. Meanwhile, it operates long-term in a marine environment exposed to salt spray, waves, and extreme cyclic loading. This presents extraordinarily harsh service conditions, placing stringent demands on both material properties and manufacturing processes.

Challenge 2: A Consumable Component Facing the Trade-Off Between Lifecycle and Cost

The cushion ring is a consumable part with a fixed lifespan, typically rated for use with 200 piles. Once exhausted, it must be replaced, creating a problematic cycle of high-cost procurement, rapid wear, and repeated replacement—a major concern for end-users.

Challenge 3: Irregular, Large Cross-Section Forging with Difficult Performance Uniformity

To fit different pile specifications, cushion rings often feature a stepped, non-uniform cross-section. Combined with their large size and heavy weight, this makes it extremely difficult to control mechanical property uniformity across the full cross-section. Material characteristics and complex hot-working processes further complicate performance consistency during manufacturing.

Our Solution:To overcome these challenges, Iraeta adopted an advanced "forging-rolling" process to manufacture the cushion ring.

We first applied open-die forging with large deformation and multi-directional hammering to thoroughly refine coarse grains within the billet. This was followed by radial-axial ring rolling, a continuous forming process in which the fiber flow lines of the metal align with the circumference of the part under strong rolling force—resulting in excellent impact resistance, longer service life, and improved piling performance.

Compared to traditional open-die forging, the forging-rolling process requires fewer heating cycles and offers higher forming precision. This reduces both machining allowance and energy consumption, enabling faster delivery and lower production costs—a clear advantage in cost control and lead time.

As offshore wind turbines grow larger, foundation diameters are also increasing. Tower base flanges now exceed 12 meters in diameter, requiring larger monopiles and larger cushion rings. Traditional open-die forging is increasingly constrained by press column spacing, limiting its ability to support ultra-large ring production. In contrast, Iraeta’s forging-rolling process is virtually unrestricted in cushion ring diameter and height, making it ideal for next-generation offshore construction needs.

To date, Iraeta has successfully produced six 100-ton-class cushion rings, solidifying our leadership in near-net shape large ring forging. We operate with advanced production equipment and extensive experience in mass manufacturing. Our capabilities include forging rings with diameters up to 22 meters and heights up to 5 meters.