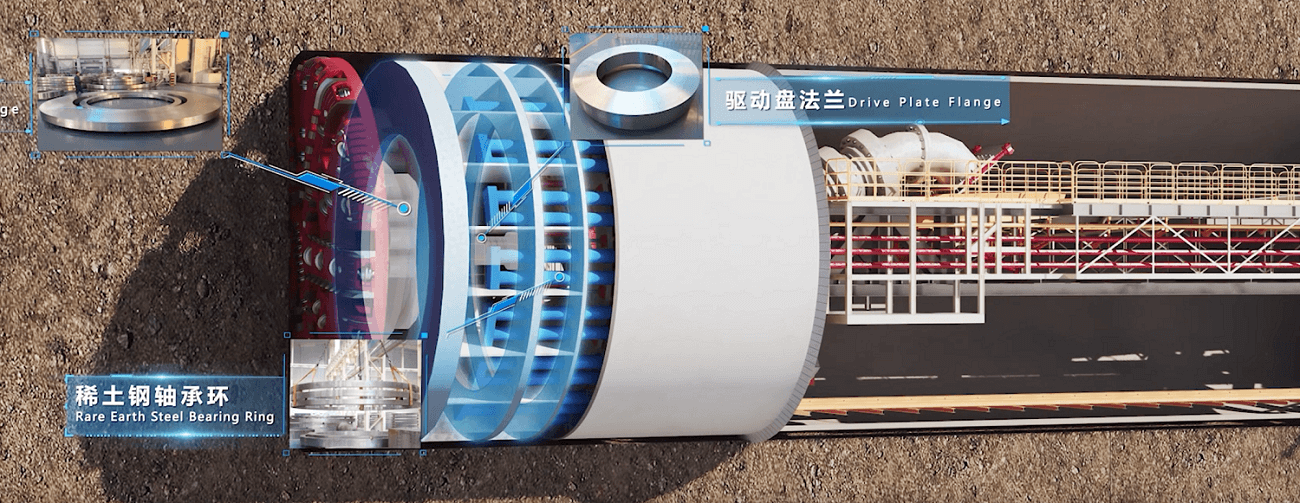

Project Background:China Railway Construction Corporation (CRCC) is a globally recognized manufacturer of tunnel boring machines (TBMs) and a leader in underground construction technology. In 2023, CRCC planned to build a super-sized TBM with a cutting diameter of 18 meters. The main bearing of this machine weighs over 60 tons and is as tall as a three-story building. Its development posed multiple world-class technical challenges.

Challenge 1: Underground Operation Requires Exceptional Quality

The main bearing is the core component driving the TBM. Its quality requirements are extremely demanding. Once the TBM starts operating underground, the main bearing becomes virtually irreplaceable. Any failure could halt the entire tunneling project and result in repair costs exceeding tens of millions of RMB. Although Iraeta does not manufacture the bearing itself, we supply the bearing rings, which serve as the main load-bearing elements. Any minor defect in these rings could trigger chain-reaction failures.

Challenge 2: Complex Loading and Extremely High Performance Uniformity Requirements

The main bearing must simultaneously withstand axial thrust (the propulsion force during excavation), radial load (earth pressure and machine weight), and tilting moment (unbalanced forces from cutterhead rotation).As the cutterhead rotates, the direction of the load changes cyclically.

Put simply, the main bearing is like a person doing three things at once:

pushing forward with great force using their hands (axial thrust);

carrying a heavy load on their shoulders (radial load);

and trying to stay upright while resisting spinning forces (tilting moment)

and all three actions are happening in a continuous cycle.

These complex and dynamic loads demand extremely high mechanical property uniformity around the full circumference of the bearing ring. Otherwise, uneven stress distribution can occur, leading to localized stress concentration, which in turn may cause cracking or deformation.This can result in premature localized wear or spalling of the bearing, directly affecting the service life of the TBM.

Challenge 3: Size Effect Brings Technical Complexity

The performance of a bearing ring is primarily determined by its material and thermal processing (forging and heat treatment). For large rings with diameters over 3 meters, achieving the required mechanical properties and uniformity through heat treatment presents a major challenge. The larger the size, the more significant the uneven cooling effect, often resulting in undesirable structures like surface hardening with a soft, brittle core, which directly undermines load-bearing capacity.

Our Solution:Iraeta’s advanced equipment and deep experience in ring forging laid a solid foundation for this project.

We used our 16-meter SMS ring rolling machine from Germany, which applies high rolling force to ensure full deformation of the forging. The ring is formed in a single, precise pass, reducing the number of heating cycles and ensuring tight dimensional control.

We also operate an intelligent water quenching system with a maximum spray agitation rate of 7,200 m³/hour and a water circulation rate exceeding 2,800 m³/hour—meaning more than 2,800 tons of water flow through the system every hour. In addition, we have a dedicated cooling system that prevents the quenching medium from overheating, solving the issue of uneven cooling during the heat treatment process.

Our heat treatment engineers, each with over 15 years of experience, use a combination of simulation software and historical data to design optimized temperature profiles. As a result, the hardness variation of each forging is controlled within ≤20HB, ensuring excellent hardenability and uniformity.

These combined strategies enabled us to successfully deliver the critical bearing rings for the TBM’s main bearing. The product’s performance and consistency met or exceeded the technical standards of leading companies both domestically and internationally.

We are proud to be a core forging supplier to leading companies such as CRCHI, China Railway Engineering Equipment Group, and CCCC Tianhe.